- Have any questions?

- +91 9210626626

- info@markolaser.com

Laser Hallmarking, Engraving, Cutting of Rings, Bangles, & Pendant Jewelry

Engraving

Discover More...

Cutting

Discover More...

Hallmarking

Discover More...

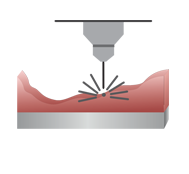

Inner Marking/ Hallmarking/ Engraving on Cambered Ring

BIS Laser hallmarking, marking for branding and engraving inside the round surface of cambered rings requires high skills. We at Markolaser have mastered these skills.

- Laser marking & engraving with URSA

- Laser accessory – Rotary

- Laser marking with Orion

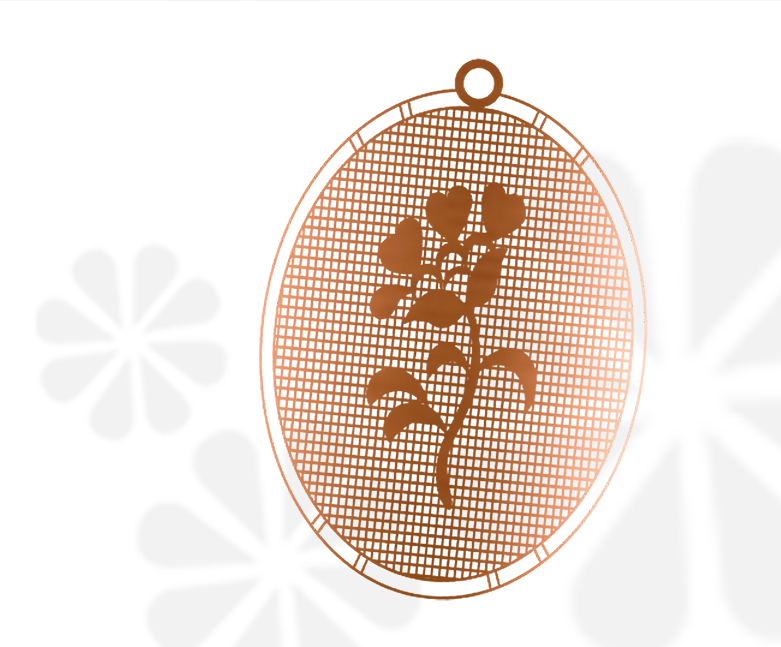

Laser Cutting in Jewellery Designing

Filigree cutting by laser is one of the important applications used to design jewellery. For this application we have extra fine & high frequency lasers with a number of waveforms that make it possible to work with materials such as brass, aluminum, stainless steel, titanium, German silver, copper, wood or acrylic etc.

Some of the important features are as follows:

- During cutting , it does not produce too much HAZ

- The material deformation is negligible

- It produces very fine cutting edges or walls

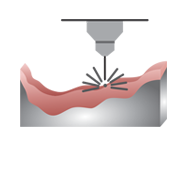

Circumferential Seamless Laser Engraving/ Marking on Ring

Circumferential seamless laser engraving/ marking on rings/ bangles is one of the challenges faced by the jewellery industry. The precise laser system with a rotary attachment and a numeric controlled dividing head and a preview of the result on a screen ensure great precision.

- Laser engraving with URSA

- Laser accessory – Rotary

LASER CRAFTING

When it comes to modern jewelry designing, an extremely precise laser is needed to covert every piece of jewelry into a piece of art. Our low-power lasers are designed to create beautiful jewelry. The German quality precise lasers are known for their strength in creating beautiful jewelry.

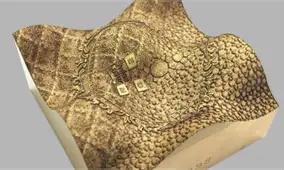

3D Texturing - Engraving - Precision Hallmarking - 3D Engraving

Color Annealing Taper Free Drilling (Thin Materials)

Special Ceramic Processing - Leather Texturing

MACHINE SPECIFICATIONS

|

Class 1 | Laser Marking, Engraving, Deep Engraving, Texturing. |

|---|---|---|

|

Max work piece weight | < 25kg |

|

Normal Part Dimension: | 300x500x200 mm |

|

Mechanical Dimension: | 882x1100x1890 mm |

|

Safety Goggles | Always Wearing Safety goggles |

|

Material | Metal, Plastic, Composite |

Machine Application

2D laser deep engraving

Laser 3D freeform texturing

Laser annealing and colouring

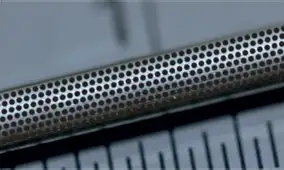

Laser drilling on metals

Freeform 3D texturing

Laser step

marking

Benefits of the Laser Engraver & Cutting Machine

● Unlimited number of usage hours on the laser source during the 2-year warranty** period..

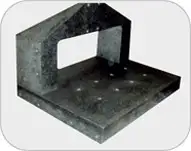

● Optional granite base and granite axis portal for highest level of precision and repeat.

● Accuracy

● Programmable servo Z Axis with positioning accuracy of ± 50 μm.

● Safety - class I safety with motor driven electrical safety door and laser protection glass.

● Small machine footprint.

● Unlimited number of usage hours on the laser source during the 2 year warranty** period.

● Caster wheels for convenient movement and anti-vibration pads for added stability.

Laser Marking, Engraving & Cutting Samples

Laser engraving

on ceramic

Leather strip die marking by

deep engraving on metals

Laser fine cuting

of gold

3D textured

die and mould

laser marking

on watch bezels

Laser deep engraving

of punch die mold

laser deep engraving on hard

metal for dies & mold making

Laser micro drilling

on metal

Supplementary Options

Customized user control interface

Motorized rotary

axis

Motorized XY axis for pelletization

Force 3+ fume extractor

Granite base & Z-axis portal