This recommendation letter is with respect to a *3D Texturing Laser machine”(3axis laser marking machine) procured by National Institute of Technology Srinagar, Under TEQIP II from Mr. Vineet Jain (M.D) of M/S Spinks Impex, MARKOLASER, a Laser manufacturing company in Gurgaon. The machine was initially procured to conduct 3-Dimensional texturing exercises on samples like Silicon Carbide, Titanium alloys, and a certain range of Polymer composites.

From the initial stages, trials were conducted at the supplier venue itself by a team from the Laser Department. The results achieved were quite pleasing and appealing. Support was provided enormously by the Laser Department of Spinks Impex towards the data collection and technical compilation of criteria essential for conducting preliminary

analysis and research documentation, while the machine was still in the development stage. Upon receiving the order for the machine, work was done at a fast pace as per the decided specification at NIT Srinagar, and the machine was delivered as per the stated time. Installation was conducted in two phases; Firstly by Mr. Neal Dcunha, a Laser Engineer of Markolaser, who had installed and commissioned the Laser machine as well as ran preliminary tests for the samples to be textured in under three days and secondly, 3D texturing and application- training was given by Mr. Abhishek Beohar, the Research and Development (Applications) Manager of Markolaser. The team at Markolaser was very helpful so as to even conduct a 10-day training regime for the students responsible for operating the machine. Overall, good results were produced with highly effective co-operation by a responsible Sales, Application, Dispatch, Technical, Service and Development team. This machine is highly recommended for research projects and for trademark applications. Spinks Impex offers no compromise to quality and strict adherence to standards. We highly recommend Laser Machines by Spinks Impex.

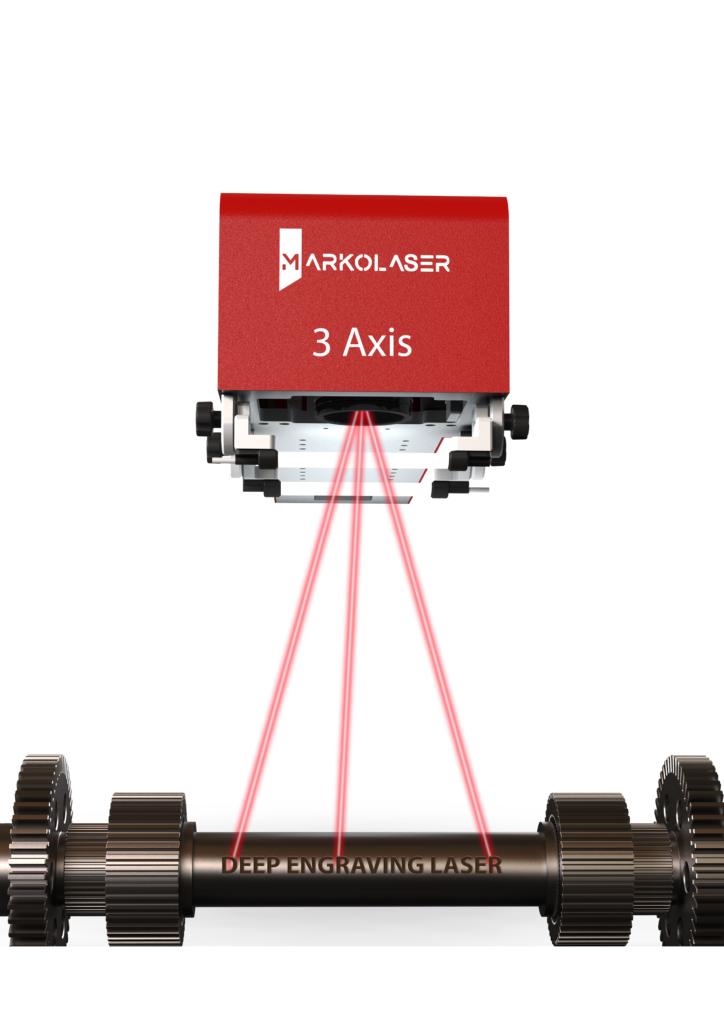

High-speed marking and deep engraving capabilities

Apart from offering high Speed & Power output, it permits the users to select the optimal and right laser irradiation method to suit the application and substrates of different hardness. This Serves perfectly and improves the marking quality, and reduces the marking time. Both of them are some of the prime factors for the manufacturing industry.

Flexible installation of laser marking head and sources with great service and technical team

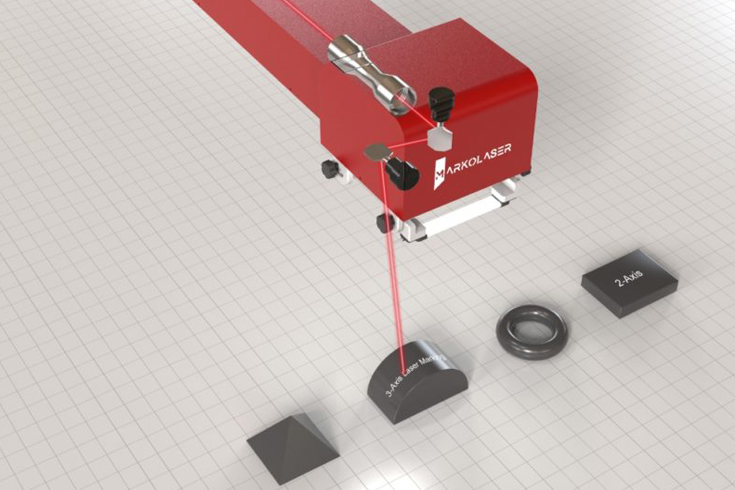

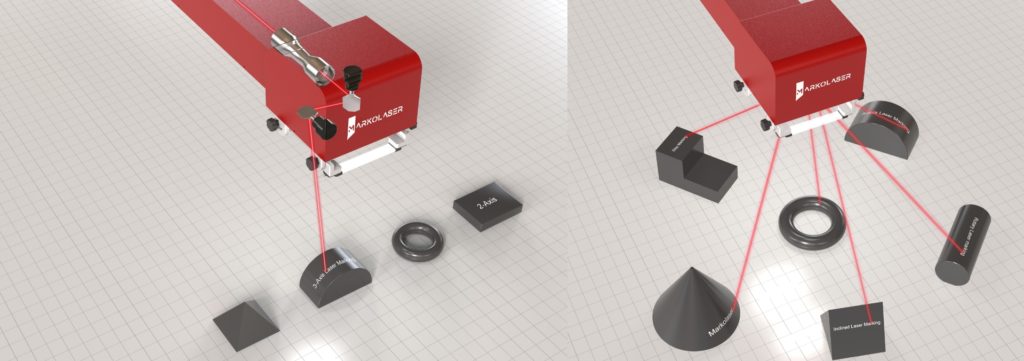

The 3-axis Laser Marking control mechanism enables clean and crisp marking not only on 2D flat surfaces but also on 3 Dimensional Curved shapes. This Autofocusing feature reduces the effort and time taken to spent on tooling changes while changing products of different curves and shapes at different levels and marking positions.

Stable, balanced operations and robust hardware designing with specialized R & D team

In addition to an environmentally resistant design, which makes it the robust, 3-Axis MARKOLASER’s machine is well equipped with all the safety features all the prime mechanism, which offers excellent and flexible operability. The capabilities to prevent problems before it begins and it reduces the time in the line. Allows a stable operation and improved productivity

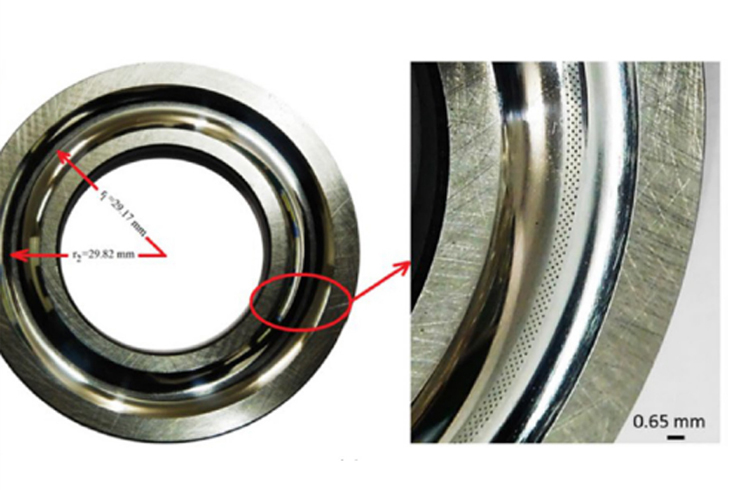

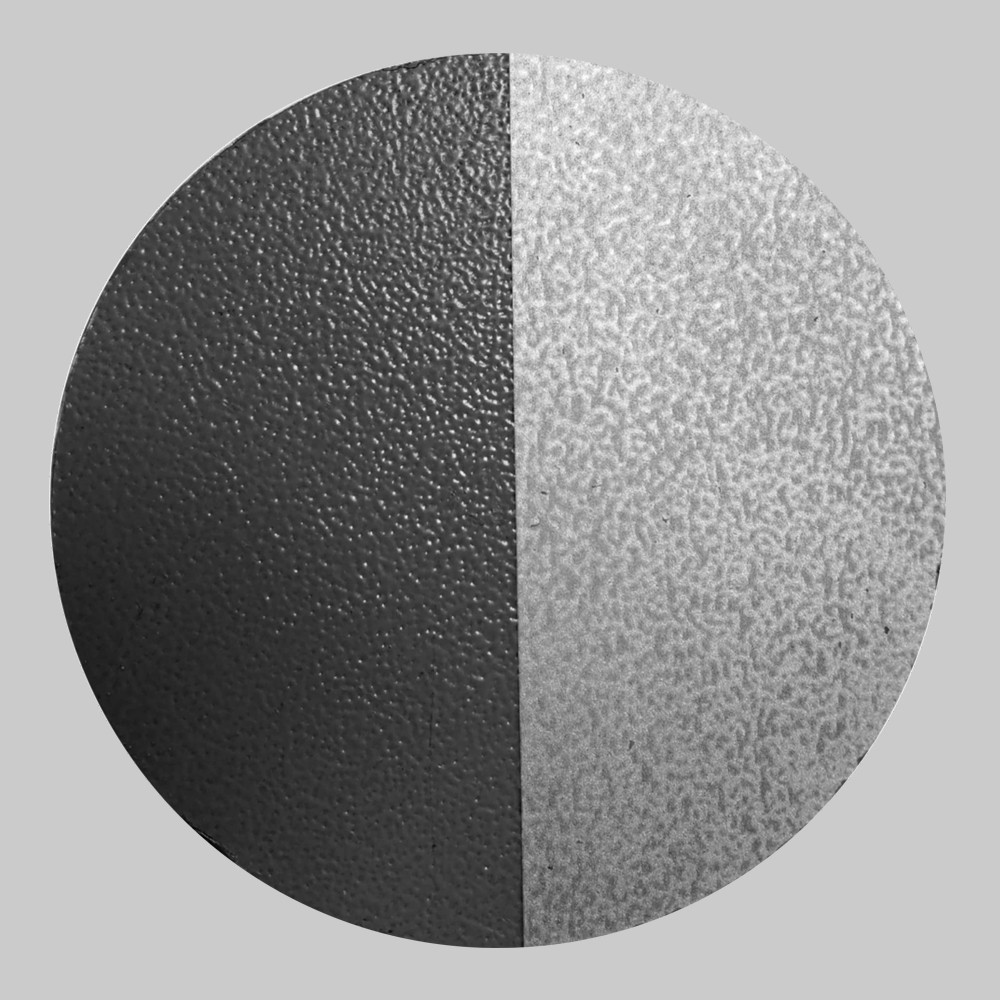

High-quality Laser Dark Annealing :

Conventional Laser Marker marks Alphacharacters lines that overlap, and energy loss is more as the laser engraving beam moves back and forth. With a specially engineered control from the engineering Lab of Markolaser, the laser moves in a circular Path /pattern, which creates a thick Alphanumeric character that keeps the energy concentrated. Elevated heat storage effect allows black annealing or marking easy.

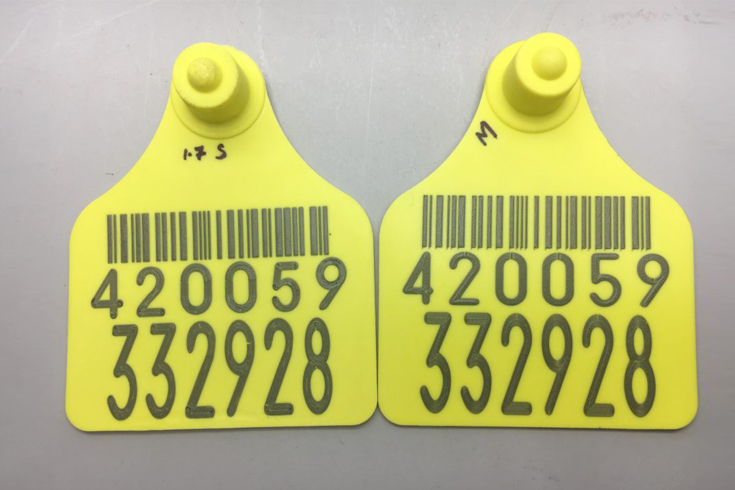

Variable Laser beam spot and de-focusing: While creating a fine Alphanumeric character that does not damage the surface of the targeted substrate, the de-focusing of laser marker works fantastically well on plastics, resins, and metals. Markolasers 3Axis Laser Marking Machine can automatically move precisely with a simple software setting and configurations, therefore, finishes the need to make physical adjustments and internally processing the correct X/Y/Z offset to eliminate mismarking and distortion.

Deep laser Marking and engraving Control: Generally, the conventional Laser Marker has a fixed focal point; the beam that engraves the target while processing it moves away from the right focal point makes it difficult to apply sufficient energy. With our Markolasers Deep engraving controllers, it becomes very easy to Change focal distance after every rotation, which allows the maximum required energy to concentrate at all the time.

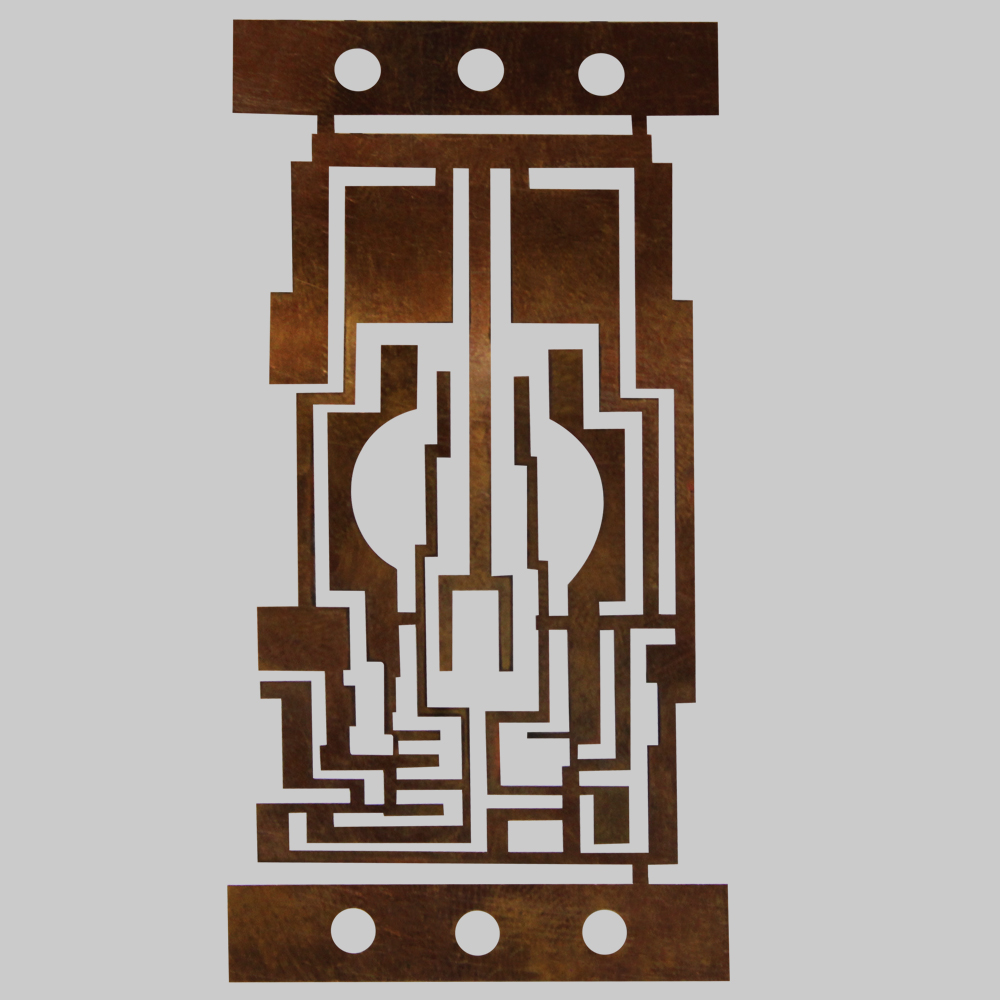

Laser Cutting: In the Conventional Laser Cutting method, the laser beam moves back and forth across the cutting width makes it difficult to keep the energy concentrated in the right place. There is a loss of energy at the Cut width. With a Specially engineered Scratch controller from Markolaser, Laser processing helps Laser beam to move back and forth in Short Distances and Lengths. This allows the beam to focus the right amount of energy, which reduces and improves the processing time

3D/ Axis Laser marking capability: The 3Axis Laser Marking Machine is well equipped with a 3-axis Laser controller. Its function is to control the Laser beam to hit the right spot that matches the target shape, includes Step, inclined, cylindrical, and cone shapes and targets. Alphanumeric distortion and flaws are kept to a minimum, resulting in a beautifully clean and crisp laser marking that fit the 3D shaped material.

Auto-focusing feature of 3 axis Laser Marker with advanced system and mechanism allows a consistently focused marking. Blurred laser marking due to deviation of a focal point is prevented. This not only reduces production costs but also contributes to improvements in the quality of laser marking. Allows reliable marking, which requires high accuracy.