What is Laser Cutting?

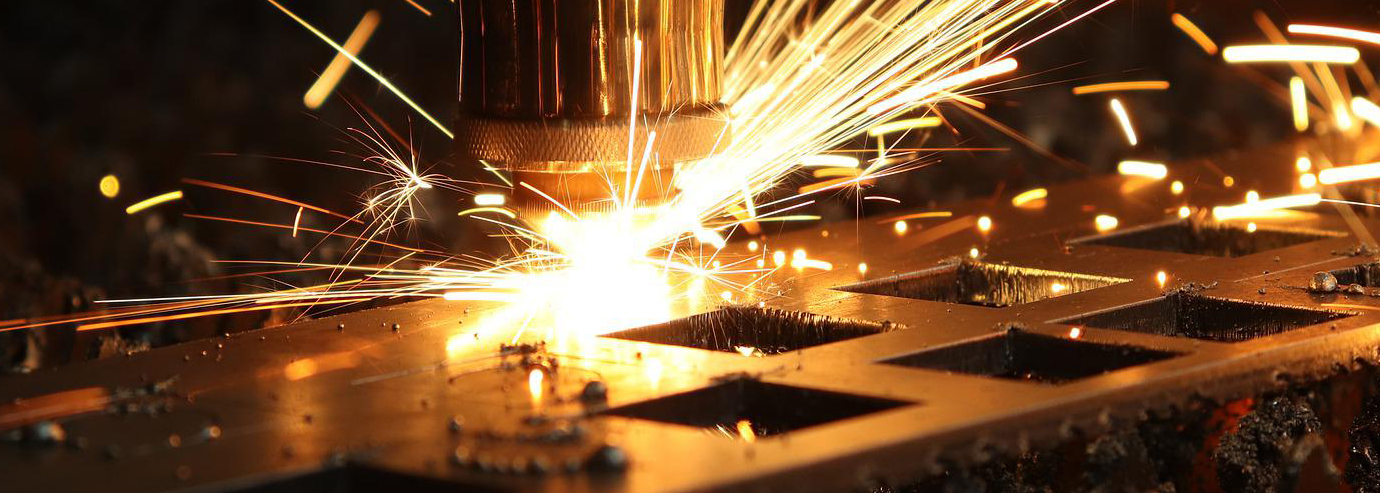

Laser cutting is the method that uses an amplified beam of light to melt the product(substrate) so precisely that it creates a clean, sharp edge. Laser cutting machines are typically used in metal sheets, jewelry making, medical stent cutting, fine electronic PCB copper cutting (both low power and high power cutting applications). The combination of beam and CNC is used to cut different metal sheets, woods, and plastics. High-power commercial lasers are used for cutting products in any pattern and design with the help of G-code.

Laser cutting is an advanced cutting technology used by various industries like medical, jewelry, furniture, electronics, aerospace, agricultural, construction, etc. The cutting process now becomes easy with state-of-the-art laser cutting machines. There is the use of a laser beam in the process of cutting. It gives results that are accurate, fast, and of the highest quality.

Process of Laser Cutting

This methodology uses a focused laser beam to do cutting on the required material. The laser beam is focused through a lens on the working area. During the process, it removes the material using vapourization. The entire process is controlled by CNC i.e. Computer numerical control or laser optics. It means it is controlled by a system. Laser cutting frameworks provide superior cut quality and are quick in doing their work. Metal laser cutting machine is used for aluminium, copper, titanium, stainless steel, etc. For example, laser cut metal sign on house number of nameplate. Due to its creativity and excellent outcomes, the laser cutting process is gaining popularity day by day.

Advantages of Laser Cutting

- Cut hard materials with accuracy.

- Faster than the traditional laser cutting technique.

- The process uses less energy during cutting.

- Work with high speed.

- No direct contact between the laser tool and the work area.

Types of Laser Cutting Machines

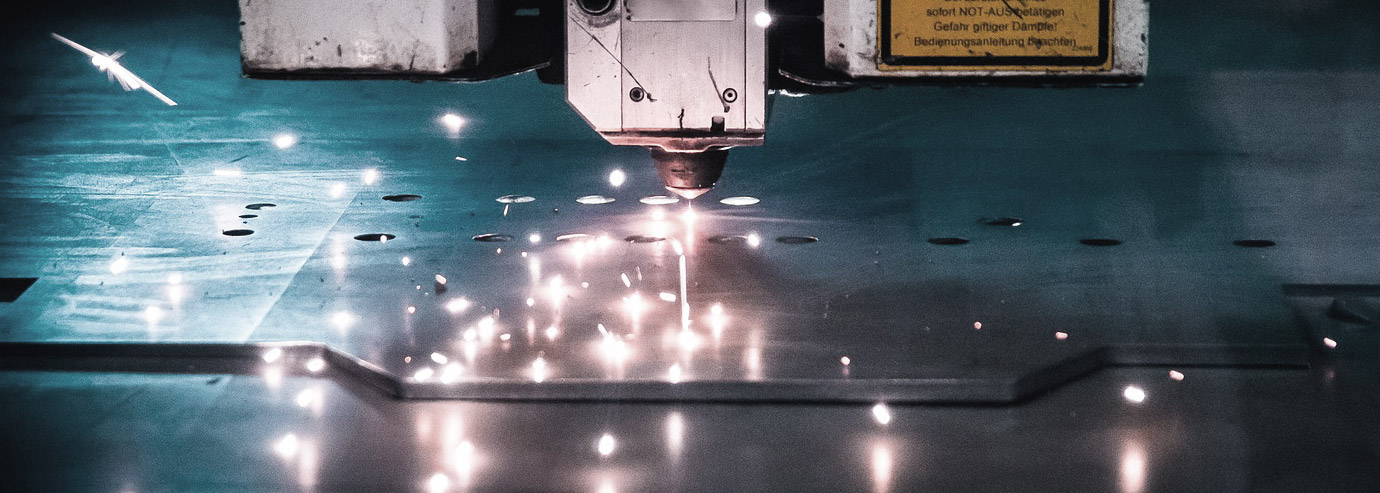

Fiber Laser Cutting Machine

Fiber Lasers are utilized in cutting, marking, drilling, and welding. These lasers uses an optical fiber as an active gain medium. The resulting laser light can be easily delivered to the targeted position. High peak power of fiber lasers enhance marking and engraving.

This framework i.e. fiber laser cutter doesn’t require more time in adjusting. Fast speed with a high conversation rate. Cutting results with fiber laser cutting technique are of high-quality. Fiber laser cutting is a reliable and flexible process that proffers benefits to various industries. These laser cutting machines deliver great productivity plus performance. High power fiber laser cutters are available for metals like aluminum, titanium, stainless steel, etc.

CO2 Laser Cutting Machine

This machine is widely used in manufacturing industries. CO2 laser is also known as carbon dioxide laser. It is one of the most successful gas laser used in today’s world. As it was invented in 1964, the industries at that time also took advantage of the CO2 laser cutting technique. The laser active medium in the CO2 laser is a gas mixture. These lasers have high-speed, high-quality, and high efficiency. CO2 laser framework consists of helium, nitrogen, hydrogen, carbon dioxide and oxygen.

CO2 lasers are used for cutting and engraving purposes. They are used for wood, paper, plastic, leather, fabric, and various others. For example, laser cutting wood i.e. laser cutting process can be used on a wooden clock to give a beautiful look to that clock.

CNC Laser Cutting Machine

CNC i.e. Computer Numerical Control, this laser cutting technology is very useful and people are using it for many years. The framework is available in small and large sizes. CNC laser cutting equipment can be used for jewelry, medical, automotive, sheet metal, and various other industries. This technique uses a high-powered beam to do its work related to cutting or engraving and creates unique designs and shapes as per the requirement. The advantage of using CNC laser cutting technology is its accuracy. This machine delivers superior cut quality on materials. The process also uses gases in the cutting process including nitrogen and oxygen etc.

Applications of Laser Cutting

Laser Cutting Jewellery

Jewelry industry designers and manufacturers are now searching for the best tools for cutting on jewelry parts. Laser systems are utilized for such precious metals as they have spiffing marking and cutting abilities. We offer you the new plus splendid laser cutting jewellery machines that are particularly meant for this industry and cut jewelry pieces with flexibility and accuracy. Creating different shapes on jewelry pieces made up of gold, silver, and, platinum is not difficult by using advanced jewelry laser cut machine.

For example, laser cutting on leaf-style earrings is possible with the help of laser cutters.

These unique systems are not only used for creating laser cutting designs on the modern style of jewellery but also used for the traditional style of jewellery.

Cutting with a laser is a non-contact process. Creating beautiful jewelry pieces is now safe and easy with laser cutting machines. Laser cutting machines are precise, reliable, and provide superior finishing. High-power fiber laser cutters are used for jewelry decoration because of splendid functionality and performance. The jewelry designer or manufacturer needs to set the machine as per the material on which the design needs to be created. Operating such machines is not a hard job, you can do it on your own.

Markolaser provides fiber laser cutters to the jewelry industry. Also, our machines proffer superlative performance when used for cutting on complex jewelry designs. For us, perfection really matters so our machines are designed in such a way that provide the highest quality and accurate results.

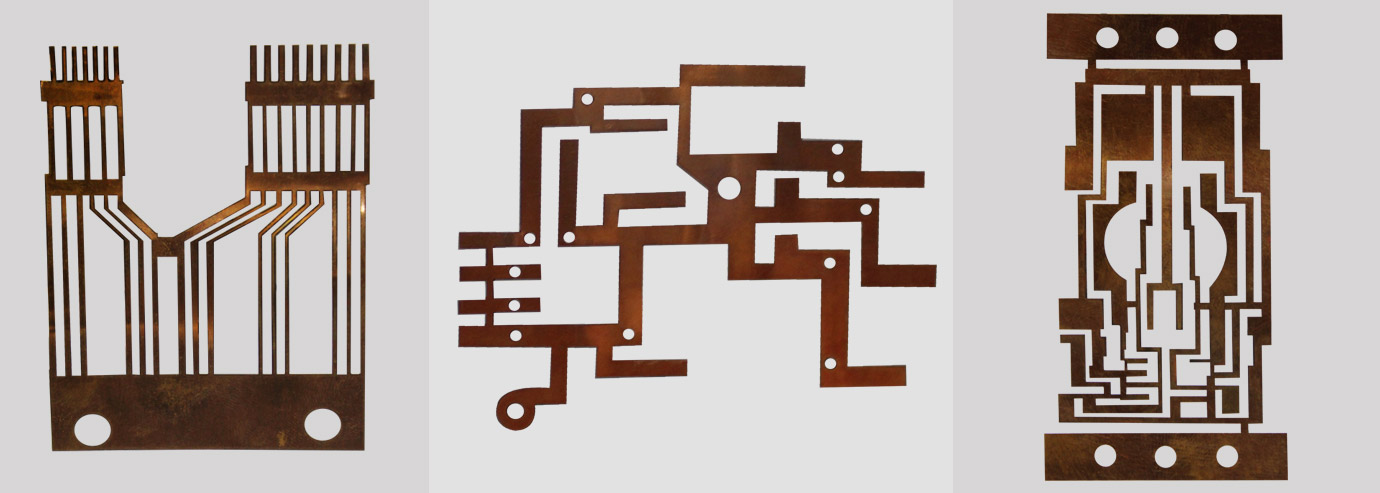

Laser Cutting in Electronics

The laser cutting technique in the electronic industry is used for various components and is very helpful for this industry. This method is the most preferred for fine cutting and where there is a need for high precision. The laser technique is a superior technology used on different materials in the electronics industry for their fast production with sharp cutting edges and accuracy.

With high standards, laser cutting tools work on different electronics components and the latest laser cutting systems are meant with proper safety and security.

For example, a laser cutting tool can be used for display panels.

Electronics Components such as display panel, PCB, diode, capacitor, and others consist of various materials. These components need state-of-the-art-machines for manufacturing. Advanced laser systems are suitable for welding, marking, and cutting on electronics components. Laser cutting when used for electronics gives fruitful results by maintaining high standards and improving production.

We can provide solutions for other industries also.

Aerospace Laser Cutting

The aerospace industry uses laser technology to enhance its performance. It is really important for the aerospace industry that every technique used here must be thoroughly checked. These laser cutting tools make aerospace work fast and easy and they can be used on different materials.

With recent changes and developments in laser technology, the aerospace industry is getting multiple advantages. Infact, it is the industry that uses laser technology on a large scale.

For example, Laser cutting can be used on military aircrafts. Laser cutting machines designed for aerospace results in more production with high accuracy and speed.

Laser Cutting Medical Devices

Laser cutting technology is used widely in the medical industry. CNC laser cutters are excellent tools preferred for this industry. Fulfill cutting requirements that are needed for medical instruments. It is possible to use laser cutting tools on a medical device that is difficult to cut i.e. during the designing and manufacturing process. Every medical instrument needs a proper shape to fit in the required place. The need of the hour is to use advanced laser cutting techniques to get fruitful results in this industry.

For example, a stent is a small tube used by doctors in a surgery known as angioplasty. Laser cutting instruments are used in such surgery equipment.

Precise Low power Laser cutting is used to cut delicate medical parts. As the medical industries are advancing laser cutting has become an important application as blessings to the OEMs of medical industries. Low power cutting application for cutting medical glasses is very useful application in medical labs and testing accessories. Cutting is really making the industries faster, helping the medical instrument and implants manufacturer by producing the product to serve the demand of medical faculty. Laser cutting and drilling applications for medical research has become boon to the medical industries saving the lives of many.

We at Markolaser feel proud to serve the medical industry with our laser cutting machine which has helped the medical surgical and equipment industries to serve its purpose.

With the development in laser technique, the latest laser machines with new features proffer the finest products in a precise manner. Medical instruments and tools are used every day in the healthcare department. Due to the enormous demand for such tools, the medical industry is using laser cutting, welding, marking, and drilling in their manufacturing. Manufacturing of all the medical device is done with utmost care as every tool and instrument is used for the patient’s body to improve his/her health. Investing on laser machines not only increases their production but also gives bug-free outcomes.

Laser cutting is a cost-effective solution, it is useful in various medical tools such as stents, needles, heart valves, endoscopes, etc. The medical industry is gaining multiple advantages from advanced laser cutting technology.

Automotive Laser Cutting

The automotive industry uses various materials during its manufacturing process. Their parts are designed carefully in order to meet different requirements. They are used in vehicle interior and exterior. Designing, developing, and manufacturing of automotive parts is done with utmost care and the laser system also plays a salient role in the entire process. Laser cutting for automotive parts is done in such a way that the end product in this process is high-quality, bug-free, and safe.

Laser tools are used at multiple stages in this industry. Advantages of using the laser method are high-quality, accuracy, and smooth results. Advanced laser cutting process is improving the manufacturing process of automotive parts.

For example, laser cutting can be used on a window lock (part of a vehicle) which is used to open and close windows. This lock is made up of plastic and is designed in that particular shape using laser cutting technology.

Laser cutting machines for automotive fulfill various requirements needed for the manufacturing of automotive parts. To maintain safety, parts used in a car must be precisely cut. Use of laser cutting in the automotive industry is to achieve great results with clean edges and reduce material waste. Fiber laser cutting machine which is used in the manufacturing industry plays a pivotal role in the automation sector. It provides spiffing cut quality with low energy consumption and is used in automobile bodies, car bodies, car roofs, car seats etc.

Highly efficient Laser cutters provide great performance and therefore improving production and there is no need for additional finishing. The working procedure that automotive laser cutters are following today is different from the traditional method. New developments and updates in laser cutting machine make this model a quick and smooth machine.

Laser Cutting Construction

The construction industry is a big industry. As per today’s demand, the construction industry needs great design and decoration. Laser technology is used at various stages in this industry. There are multiple benefits of using the laser technique with easy-to-use laser tools available in this modern world.

The construction industry uses heavy machines for cutting with laser tools on various parts. A person doing laser cutting needs great experience in the same field. CNC fiber laser cutting machines are used in the construction industry. These machines are well-known for their performance.

For example, we can do laser cutting on a thick metal sheet or it can be used for steel structures.

Agricultural Industry Laser Cutting

Laser cutting tools are available for the agricultural industry. Fiber laser cutting machine is suitable for this industry.

Best laser cutting services are available with us, contact Markolaser for more information, we are just a call away from you.