Markolaser system allows an engraver (laser deep engraving) a new opportunity to deep engrave metals much faster (4 times faster) than conventional lasers not compromising with the beam quality. The control of depth, lens setup time, the minimum taper of sidewalls are the biggest advantages of the Markolaser machines.

Marking & Engraving Metals: Short but repeatedly high and powerful laser pulses can remove even the hardest of metals. Our Lasers work very well on hardened tool metals like die-steel, EN24, EN31, brass, and even titanium alloys.

Marking: Marking can be done in two ways. Mild micron engraving looks like marking on metals. Also, high partial oxidation can result in black.

Industries: Steel / aluminum / ceramics / gold & silver jewelery / mold cavities.

Tested On Aluminum, Sic, Silicone, Silver, Gold, Tool Steel, Stainless Steel, Titanium.

Engraving

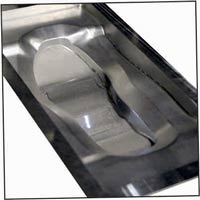

Laser engraving is the process of removing a portion of the material to leave an engraved mark which is visible beneath. The laser creates a huge amount of heat during the engraving process, which essentially causes the material to vaporize during each pulse. Several passes of the laser may be required to get the desired depth of the engraving. Laser etching is a subset of laser engraving. During the process of laser etching, the cover layer of the material is vaporized, producing little to no depth but usually, high contrast marking.

Laser deep engraving samples

For more details visit us at

Email us:

info@markolaser.com

Check-out our website for different technology

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For the jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |