Glass micro slides and Graticule slides

Laser solution marking for glass and glass micro slides made exactly of fused quartz or either borosilicate glass are used for characterization and sampling purposes. Plain slides are often used for holding liquid or powder samples under microscopy devices. The thickness of the slide varies according to the ultraviolet transparency requirement (0.2 mm-2 mm). Slides may have rounded corners for increased safety or robustness or they may have a cut-off corner for use with a slide clamp or cross-table. The edges are cut out using a diamond cutter most of the time; but lately, manufacturers are opting for more of precise-swift options like a laser for scribing their material out, for a smoother edge formation.

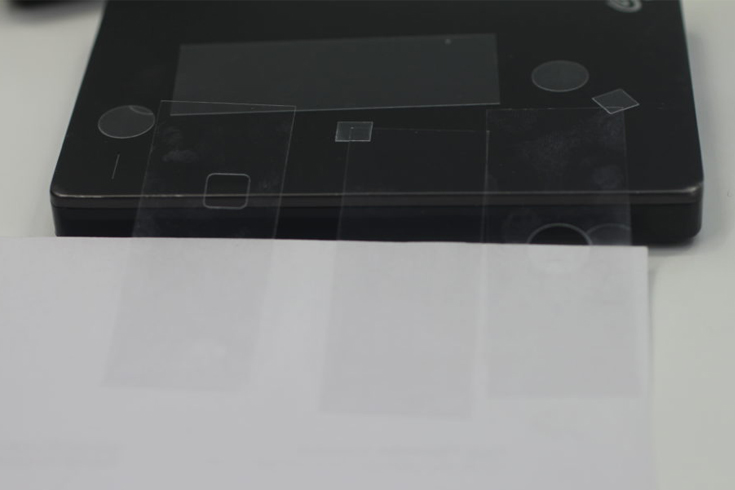

Graticule slides are marked with a grid of lines (for example, a 1 mm grid) which then allows the size of objects seen under microscopic magnification to be easily estimated and provides researchers with a reference area for counting minute objects. Sometimes, one square of the grid will itself be subdivided into a finer grid. The scale or grid is centered on a glass disc mounted in a black anodized aluminum slide and mostly used as calibration and resolution checking of microscopes and image analysis systems. The combination of scales, dots, circles, squares, rulings, grids and angles can be supplied with an internationally traceable certificate of calibration for those who require ISO conformity.

Laser Processing

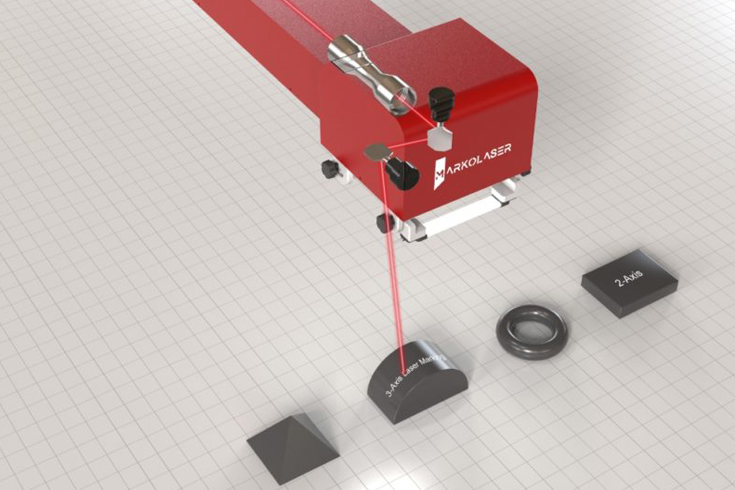

The microslide blanks are processed with Markolaser™ low wattage, frequency doubled laser source for the scribing purpose under a closed environment; providing enough air pocket under the processing stage. The sharp-cornered and round-cornered shapes are scribed out from the slide using high pulse energy of the laser. The thickness of the glass is around 0.3mm.

While, the grid marking of the graticule slides of 2 mm thickness at the center of the thickness is performed with Markolaser™ tripled frequency laser source; creating sharp micro-cracking of the cells within the glass to form a regular grid pattern of size 3×3 mm. The pulse energy is kept lower to avoid cracking of the glass more than it’s required.

Results

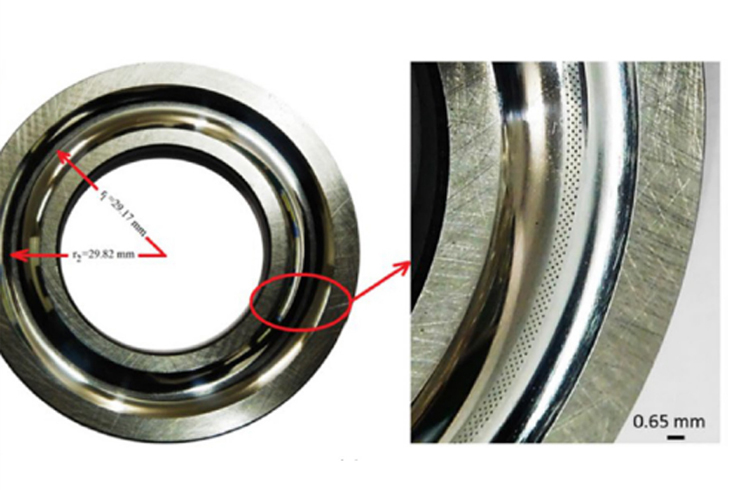

The scribing and grid marking results are captured with a 200x microscope. The scribing shows spectacular edge patterns with no signs of thermal cracking.

Laser solution sample

Check out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |

Just desire to say your article is as surprising. The clarity for your post is simply nice and i could suppose you’re knowledgeable on this subject. Fine together with your permission allow me to grab your feed to stay up to date with approaching post. Thank you a million and please keep up the enjoyable work.