KURVE LASER

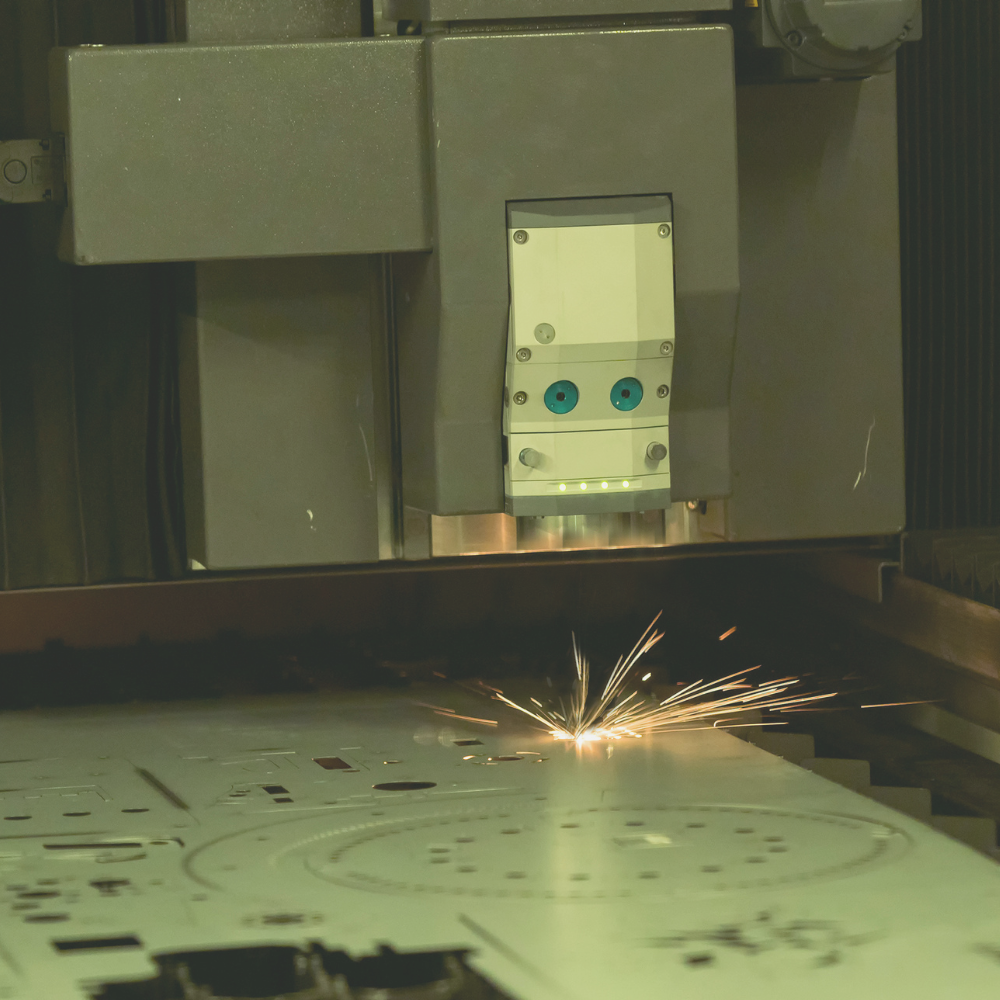

Fine Laser engraving on FREE FORM SURFACES:

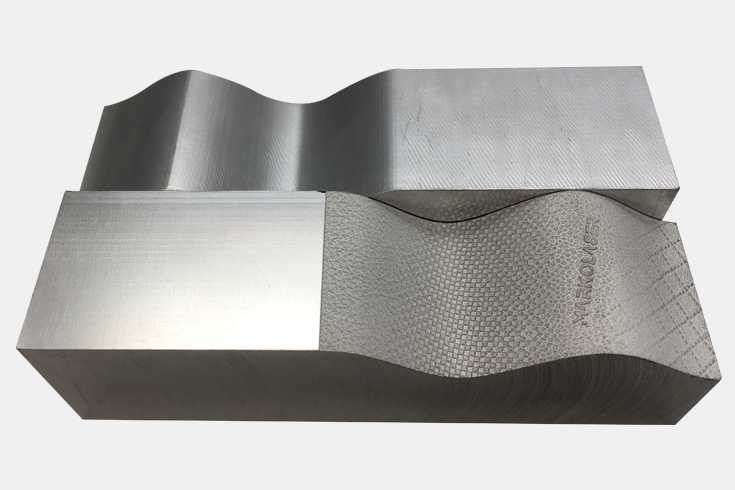

Surface laser texturing machine: There are numerous laser processing machines in the market but, hardly anyone can do a deep engraving (500 um) on free form metal substrate. If there are any, then, they are very expensive solutions.

The other solution available for such free form surfaces is CNC machining, but such machines have a limitation that they cannot do machining with a tool width less than 1 mm or 1000 um.

So, there was a need for an innovative solution that could meet their requirements of deep engraving on free form surface with a very fine tool width (as fine as 50 um) for various industries such as tools, die, injection tools and many more. Kurve lasers from Markolaser is a solution to such need.

Surface laser texturing machine examples-

A) Bottle dies – Very easy to engrave into blow molding dies made of aluminum or steel.

B) Shoe & slipper dies – Engraves sizes /logos /patterns into the aluminum dies directly. This saves a lot of time & provides immensely high precision.

C) Electrode for EDM machine – Very sharp & accurate electrodes can be made very easily with such machines.

D) Jewelry Application – Patterns can be made directly onto free forms of pendants, rings, etc. and along with our GOLDWIN, gold recovery is also possible.

E) Punches for press machines & Embossing milled – The punches can be engraved on this machine with great precision & clarity. They can be used as press tools to punch out different metals like gold, silver, tin, etc. These are used as coin dies, buttons, and for embossing, etc.

F) Reveres logos – Making sharp reverse logos onto curved stainless steel is used in watch making business or in many other such precision industries.

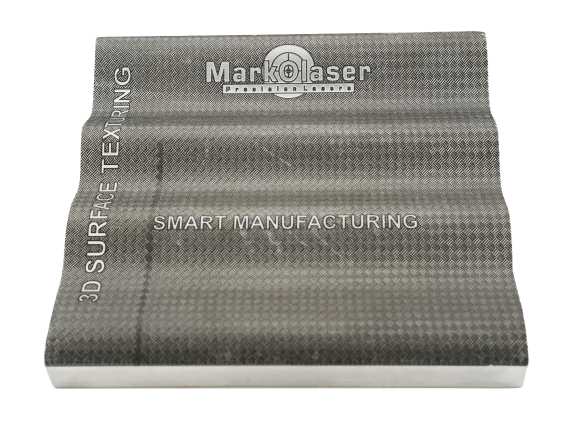

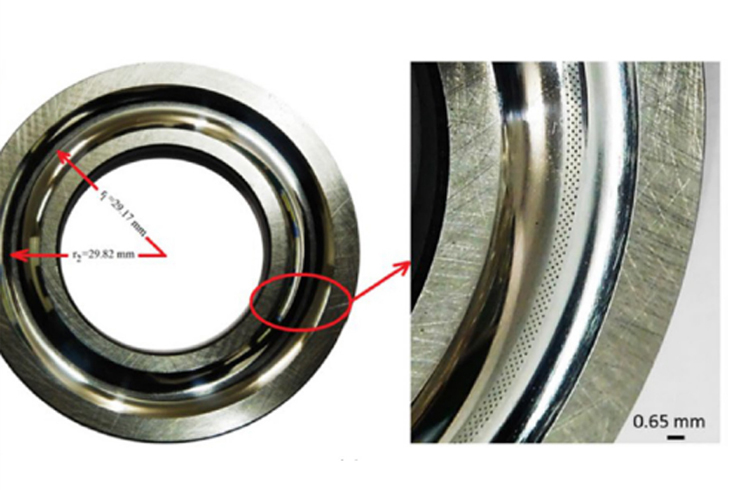

G) Textures – Making textures onto free form or curved surfaces is considered a very tedious process by conventional processes like Electro – Chemical – Etching & Electrical discharge machining (EDM) .

Our FFS -Free Form Surface laser or the KURVE laser has many inbuilt capabilities:

1) It can project a distortion-free image on free form objects without any dimensional and positional variation.

2) Alternatively, a two-axis vector design can be wrapped or projected onto a free form substrate easily. This gives the liberty to make designer textures easily onto complex shapes.

3) It can do upto 3 axis or free form deep engravings with equal ease.

4) For large parts, an X-axis slide is provided to accurately position the substrate under the laser processing area

5) Parts up to 50 Kgs can be processed, for heavier parts, special changes can be made.

6) 2½ D engraving, used for embossing and used to release the design from the press with ease, a 2½ dimensional data/ design can be processed.

7) Free form surfaces with a shape variation of +/- 20mm in height can be processed very easily, parts having even larger variations can also be processed using special arrangements.

8) Highly stable laser power ensures smooth and even engraving on the whole surface.

9) Our Kurve lasers maintain an autofocus effect throughout the surface variation to ensure the steady and stable laser beam focus while engraving the very fine pattern on it.

10) Kurve lasers are easily adaptable in any existing material process line where marking on free form surface/ semi-sphere surface is required.

| Technical data | |

|---|---|

| Safety | Class I |

| No. of Mechanical Traverses | 2 |

| Mechanical Traverses (X/Y/Z) mm | 250 / 0 / 250 |

| Over all Machine Size (W/D/H) mm | 1375 / 1100 / 1900 |

| Approx. Weight of Machine kg | < 350 |

| Work Table (W/D) mm | 600 x 400 |

| Max. Allowable Part Height mm | 150 |

| Max. Work Piece Weight kg | < 75 |

| Electrical Power Requirement AC | 110/220 V |

| Power Consumption2 W | < 800 |

| Operating Temp. °C | 5°C – 28°C |

| Operating Humidity | 15% – 85% (non condensing) |

Surface laser texturing machine samples

For more details visit us at

Email us:

info@markolaser.com

Check-out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For the jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |