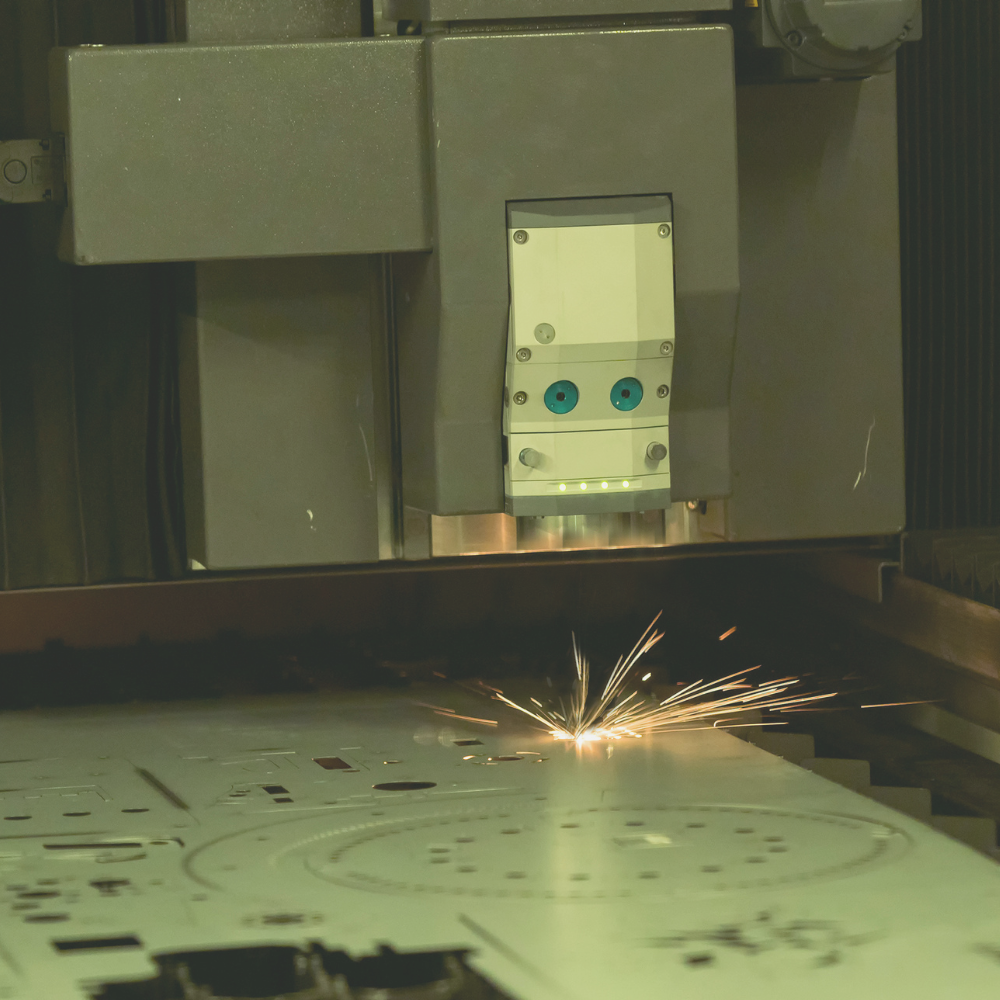

The deep engraving laser machine is a very special application of the laser industry. The need comes from the engraving of

- Hard metals with hardness above 50 HRC of steel, titanium, ceramics, etc. The conventional milling machines have to use diamond or titanium bits to engrave such metals or ceramics, which is not needed in fiber lasers.

- Another important aspect is the need to do fine engravings of about 35 microns or more. The tools for such productions are not available or even if available are very expensive.

- Speed of engraving: Some 2-dimensional engraving jobs can be done very fast by the use of laser engraving technology in comparison to the engraving done with conventional machines.

- Consumables: The fiber lasers use almost nil consumables. Only servicing is required once a year and a filter for the dust extraction system.

- Cost: The economy of working with lasers is the concluding point, which is most important.

Deep Engraving Laser machine specifications:

A laser using only 800 W per hour versus 6 KW per hour used by a milling machine. No chiller is required, which saves the cost of cooling.

The procedure of deep engraving using Markolaser express and 20/30 watt DE involves a repeated removal of the substrate material as a result of thermal laser energy in a controlled process. The calculation of parameters depending on the number of layers to be removed and the component geometry decides how deep the engraving can be done. This process is generally used to accurately mark very complex shapes and products like dies, molds, stamping tools, punches, etc. Engraving material includes steel, aluminum, copper, brass, magnesium, zinc, titanium, ceramics, and plastics.

- Deep engraving of metals especially, the tool steel needs lower frequencies for greater spot overlays. Markolaser 20 W is very useful for lesser no. of parts per day versus Markolaser 30 W which is ideal for larger productions (depending on the size and parameters of marking).

Markolaser laser system allows an engraver to deep engrave metals much faster (4 times faster) than conventional lasers without compromising with the beam quality. The control of depth, lens setup time, the minimum taper of sidewalls are the biggest advantages of the Markolaser machines.

Marking & engraving on metals: Short but repeatedly high and powerful laser pulses can remove even the hardest of metals. Our Lasers work very well on hardened tool metals like die-steel, EN24, EN31, brass, even titanium alloys.

Marking: Marking can be done in two ways:

- Mild micron engraving looks like marking on metals.

- High partial oxidation can result in black.

Industries: Steel, aluminum, ceramics, gold & silver jewelry, mold cavities, dies, buttons, embossing, and de-embossing die, punches, and roller dies to name a few.

Tested On: Aluminum, silicone, silver, gold, tool steel, stainless steel, titanium.

For more details visit us at https:// www. markolaser.com

Deep Engraving Laser machine sample

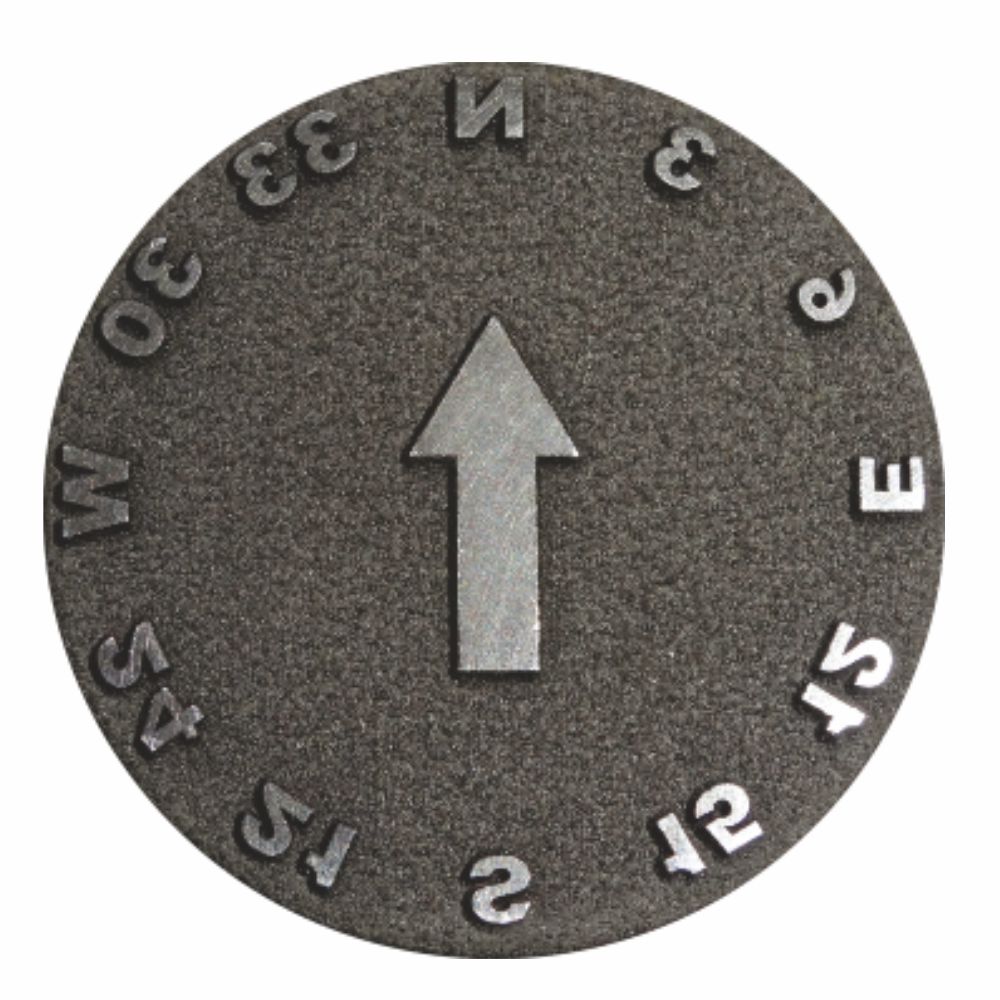

Watch dials deep engraving

Watch bezel deep engraving

Punch die for date marking

Punch die by laser

Laser surface texturing on 3D

Deep engraving by laser die

Email us: info@markolaser.com

Check-out our website for different technology

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |

We are manufacturers of laser marking machines, laser marking appliances, laser engraving machine, laser engraving application, laser etching machine, laser etching application, fiber laser marking machines, fiber laser systems, laser cutting machine, laser cutting application, laser deep engraving machine, laser deep engraving application, UV laser marking machine, UV laser marking application, Co2 laser marking machine, Co2 laser marking application, green laser marking machine, green laser marking application, laser annealing marking machine, laser annealing marking application, laser ablation machine, laser ablation application, laser foaming machine, laser Foaming application, laser Drilling machine, laser Drilling application, laser surface marking machine, laser surface marking application, laser 2D surface marking machine, laser 2D surface marking application, laser 3D engraving machine, laser 3D engraving application, laser freeform surface marking machine, laser freeform surface marking application.