QR Code Laser Marking on Lacquered Polypropylene (PP) Transformers

Material

Lacquered PP Transformer Parts

Requirement

The project required precise laser marking of QR codes on the lacquered surface of PP transformers to meet the following specifications:

-

Traceability and Identification: The QR codes must be laser marked on the lacquered surface to ensure accurate traceability and easy identification of the transformer parts.

-

Marking Effect: The laser marking needed to be black, clear, and highly visible, ensuring that the QR codes could be easily scanned and read.

-

Marking Area: The specific marking area for the QR codes was defined as 200 mm × 200 mm.

Background: Why Lacquered PP Transformers?

Polypropylene (PP) transformers are commonly used in the electrical industry due to their excellent insulation properties. To enhance their performance, these transformers are often lacquered for the following reasons:

-

Insulation Improvement: The lacquer serves as an additional insulating layer, preventing short circuits and maintaining the transformer's dielectric strength.

-

Durability and Safety: Lacquering significantly improves the durability of PP transformers, making them more suitable for demanding industrial and outdoor applications.

The Challenge

Laser marking on a lacquered surface presents unique challenges, particularly when trying to achieve clear, black, and visible QR codes. The lacquer's reflective properties can affect the laser's marking accuracy, requiring precise adjustments to ensure the desired effect.

Solution

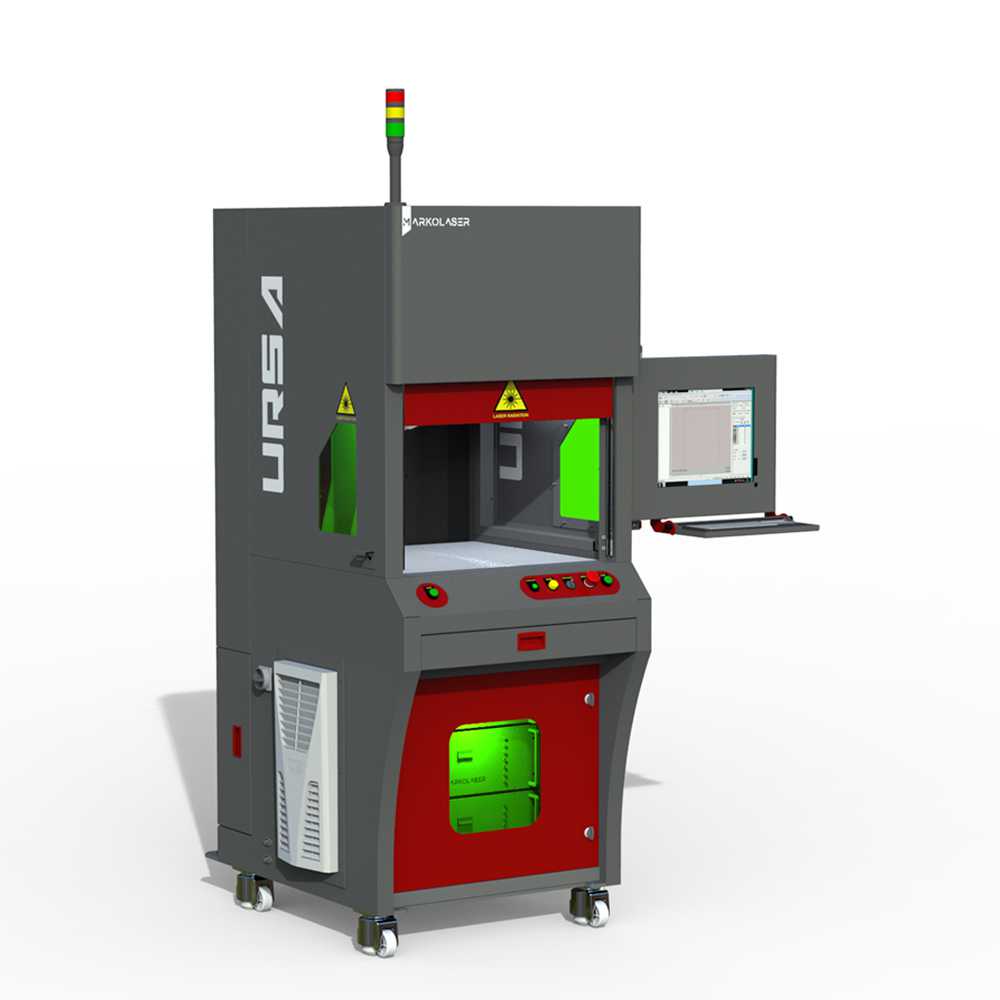

Using a high-precision Markolaser laser marking system, the QR codes were successfully marked onto the lacquered PP surface. The process was optimized to achieve the required black, clear, and visible markings within the specified 200 mm × 200 mm area.

Outcome

The Markolaser laser-marked QR codes on the lacquered PP transformers provided excellent traceability and identification while maintaining the integrity of the lacquer coating. This solution ensured compliance with the industrial standards for transformer identification and tracking, enhancing both quality control and product traceability in the electrical industry.

Note: We cannot show pictures of the samples , names, or applications here due to a non-disclosure agreement with our client. Write to us if you wish to know more details.