- Have any questions?

- +91 9210626626

- info@markolaser.com

Markolaser Label Pro

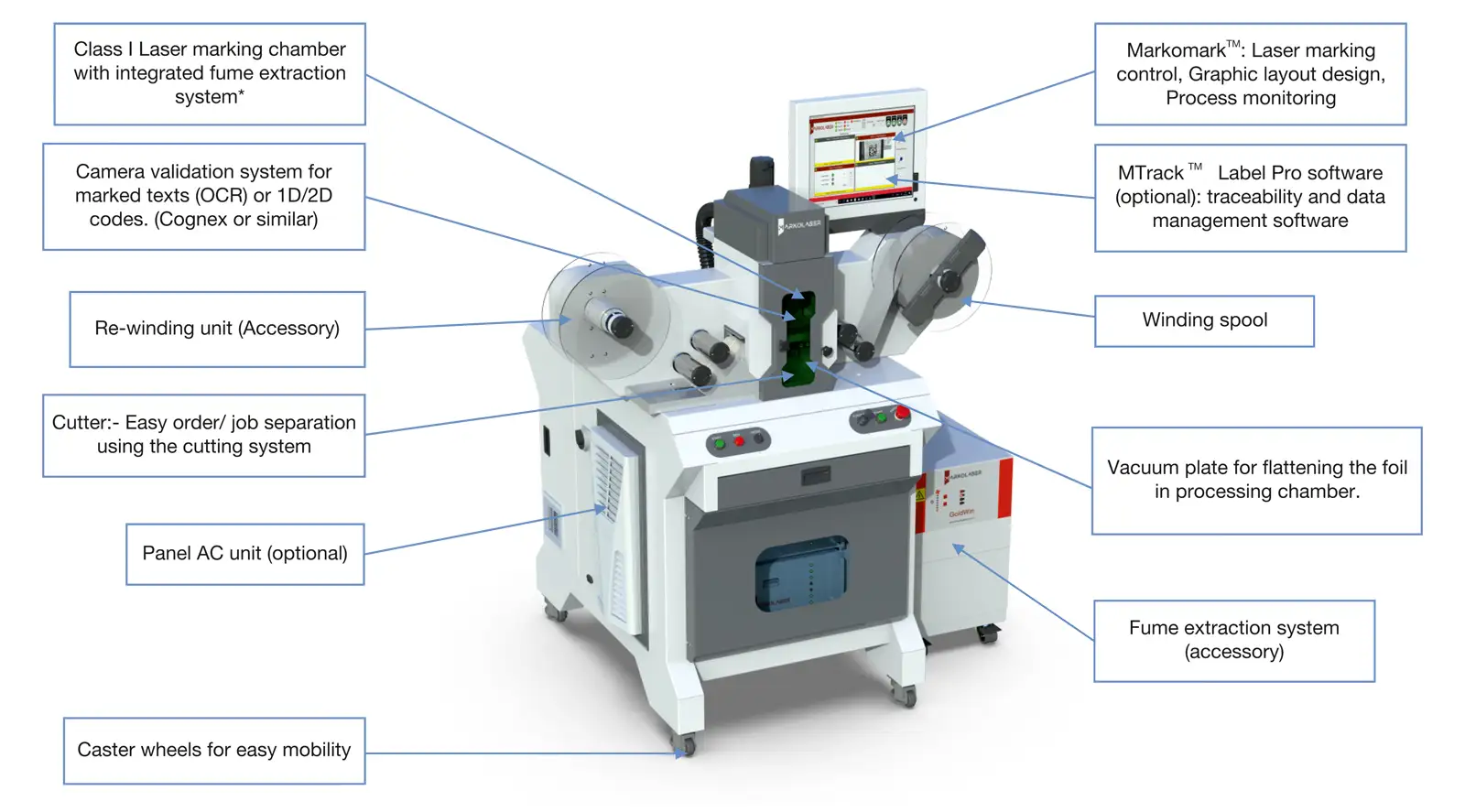

Markolaser Laser label marker is a dedicated system for precise, high-speed marking and kiss cutting of laser specialized security labels, VIN Foils and other laser-able continuous materials of different sizes.

Straight from the rolls, cut them out or re-wind again into rolls without the need of additional tools.

Salient Features

- 1064nm & the flexibility of different laser wavelengths (like CO2 etc.) and optical configurations.

- Cutting & marking done is in one process.

- Flexibility in marking & label size cutting (e.g. sequential series num bers, Variable and dynam ic data integration, ERP and MES integration etc.)

- Excellent results on Double-layered Acrylic security labels (NHTSA, EEC, GB, complied labels ) & other laser-able security labels.

- Foil end warning

- Label widths: Standard 100mm or 120mm and up to 180mm upon request.

- ERP and MES integration via. MTrack® Label Pro.

- IOT 4.0 interfaces necessary for programming and data transfers available.

- Integratable in complex production processes.

Marked & Kiss Cuton TESA 6940 Security Label With Markolaser Label Pro

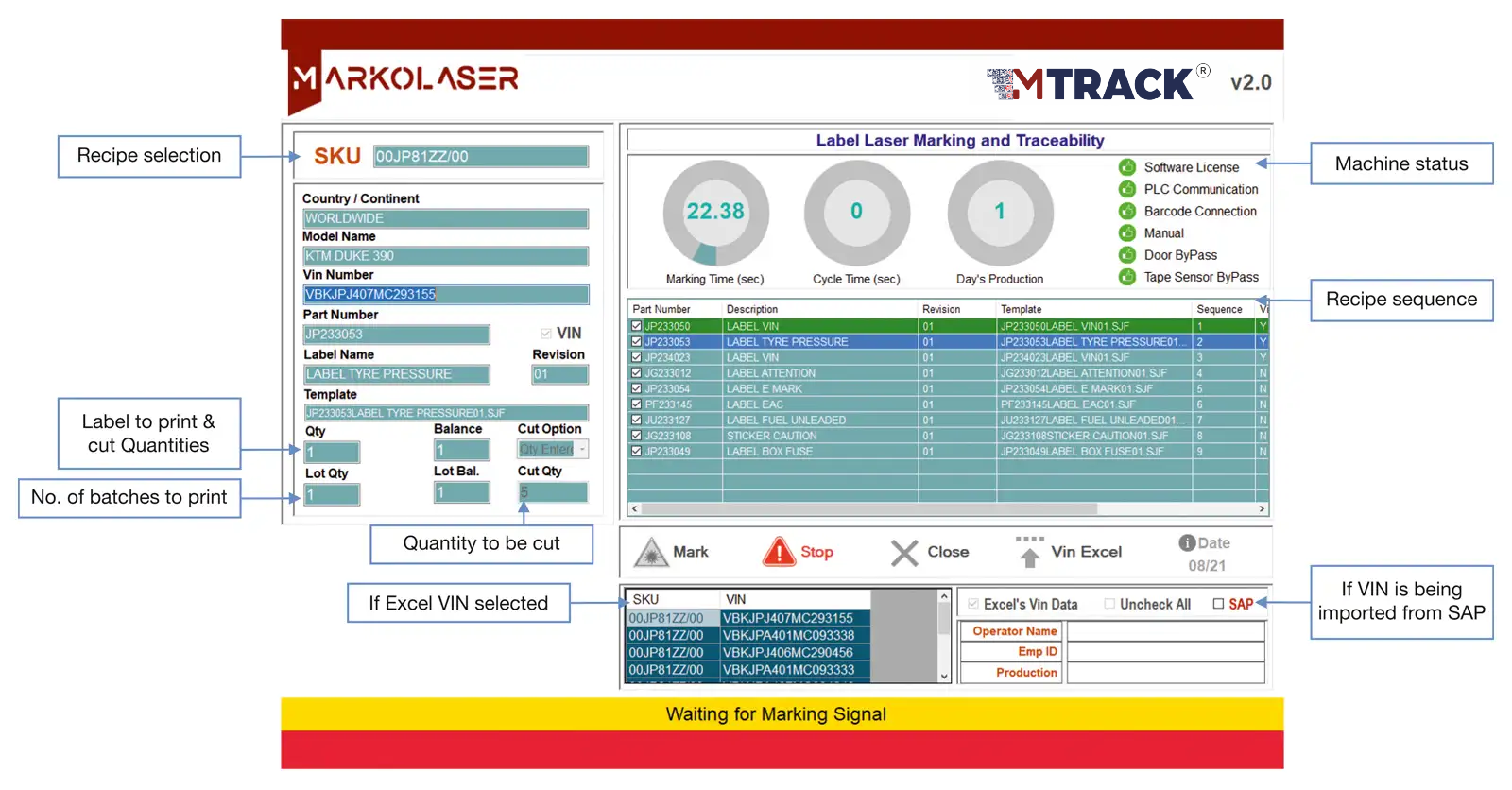

MTrack ® Label Pro

Customized traceability & data management software for Markolaser Label Pro

- Online/Offline database integration and management: MS Access, SQL server, Oracle, DBase, Informix, Paradox, Foxpro & others.

- MES & ERP integration (Optional)

- Remote Management system (Optional): If the lasers are integrated in complex production processes. Objects & parameters, Layouts & variable data can be set, administered & processed externally via. PC / PLC.

- Customizable GUI as per customer requirements

- Implement full label set system using Mtrack® Label Pro.

- Seam less Integration with Laser System, PLCs & Barcode Scanners.

- Remote Host operation.

- IOT 4.0 interfaces necessary for programming & data transfer savailable.

- Other features not limited to recipe management, process monitoring, production management,batch control, user based access management, machine health status.