We make the supply chain management system easy and hassel free

Traceability solutions for raw materials, from the source of manufacturing a product for substantiality, brand protection, safety and Reliability. This way we will be able to identify the exact raw material that is involved in producing the product

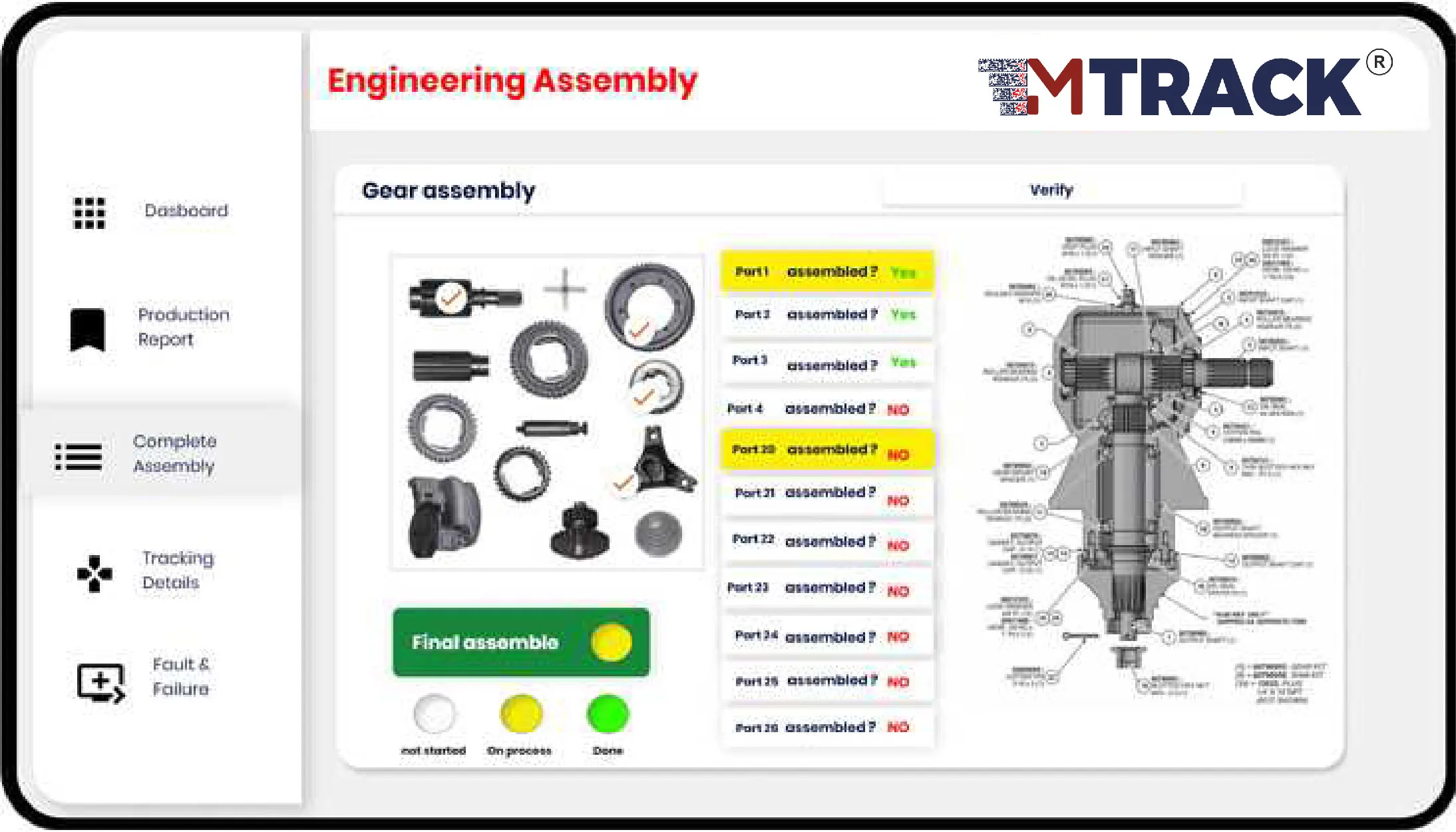

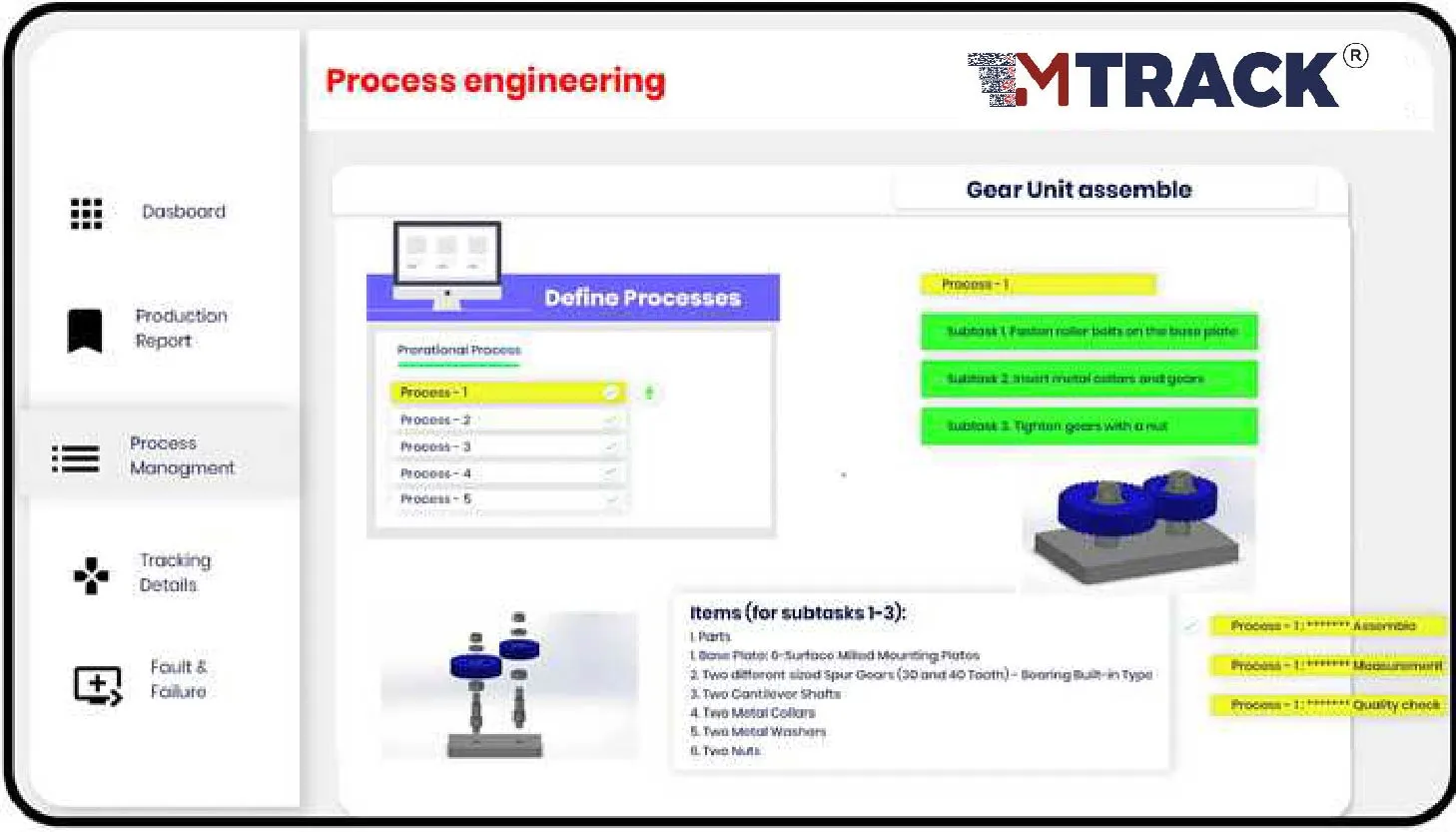

In the Manufacturing plant, internal traceability and process traceability have great significance. For example, a gear and bolt belonging to its gear assembly can only be traced by the unique identification number assigned to each part. Traceability solution will help in fulfilling regulatory compliance, Transparency & operational excellence till it gets Shipped or stored in Warehouse

Traceability solutions for Distribution network, Warehouse, Logistics for Authentication, regulatory compliance, genuine product, theft management, Timely delivery to the supplier and distributor

Traceability solutions for creating a long term relation between brand owner and end consumer, Consumers engagement, educating consumers, marketing insight and Product transparency/ identification.

Traceability solutions for recyclable materials, waste management, reusability and reduce the use waste. Traceability solution will helps use identify the right recyclable product. Which will result in reduction in the price of buying the raw material.

What Markolaser Solution offer you: traceability solutions module for Businesses

Improves Operational excellence

Achieve Compliance

Improve Brand recall

Combat fraud & counterfeiting

Secure Supply

Establish proof of origin

Increase product safety

Transparency & Authetication

Improve Consumer Locality

Provide product visibility

Trace & track Inventory

Product cycle assement

Single Software Solution for Digitization of complete Supply chain

Real-Time Visibility and Control on Operations

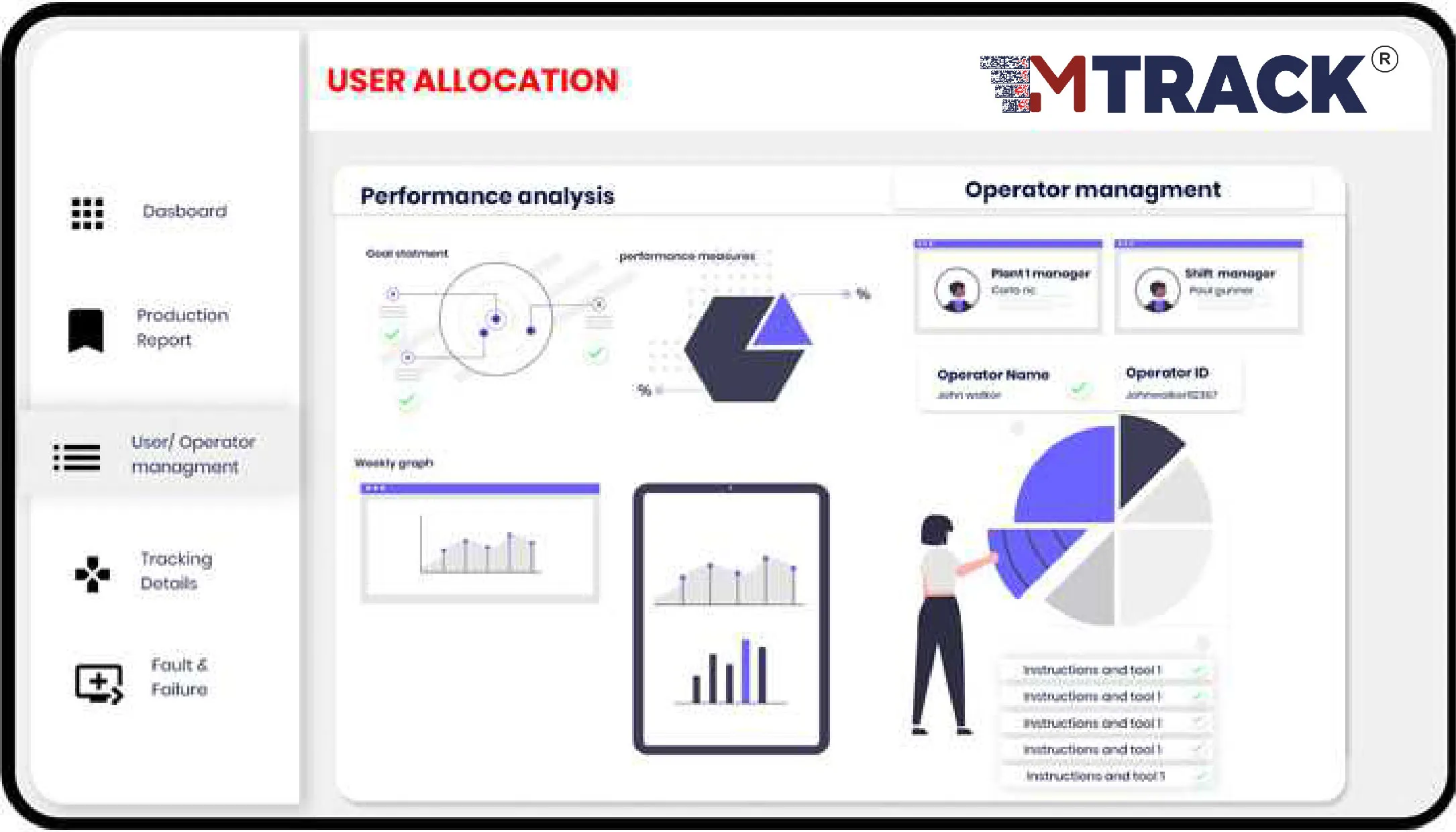

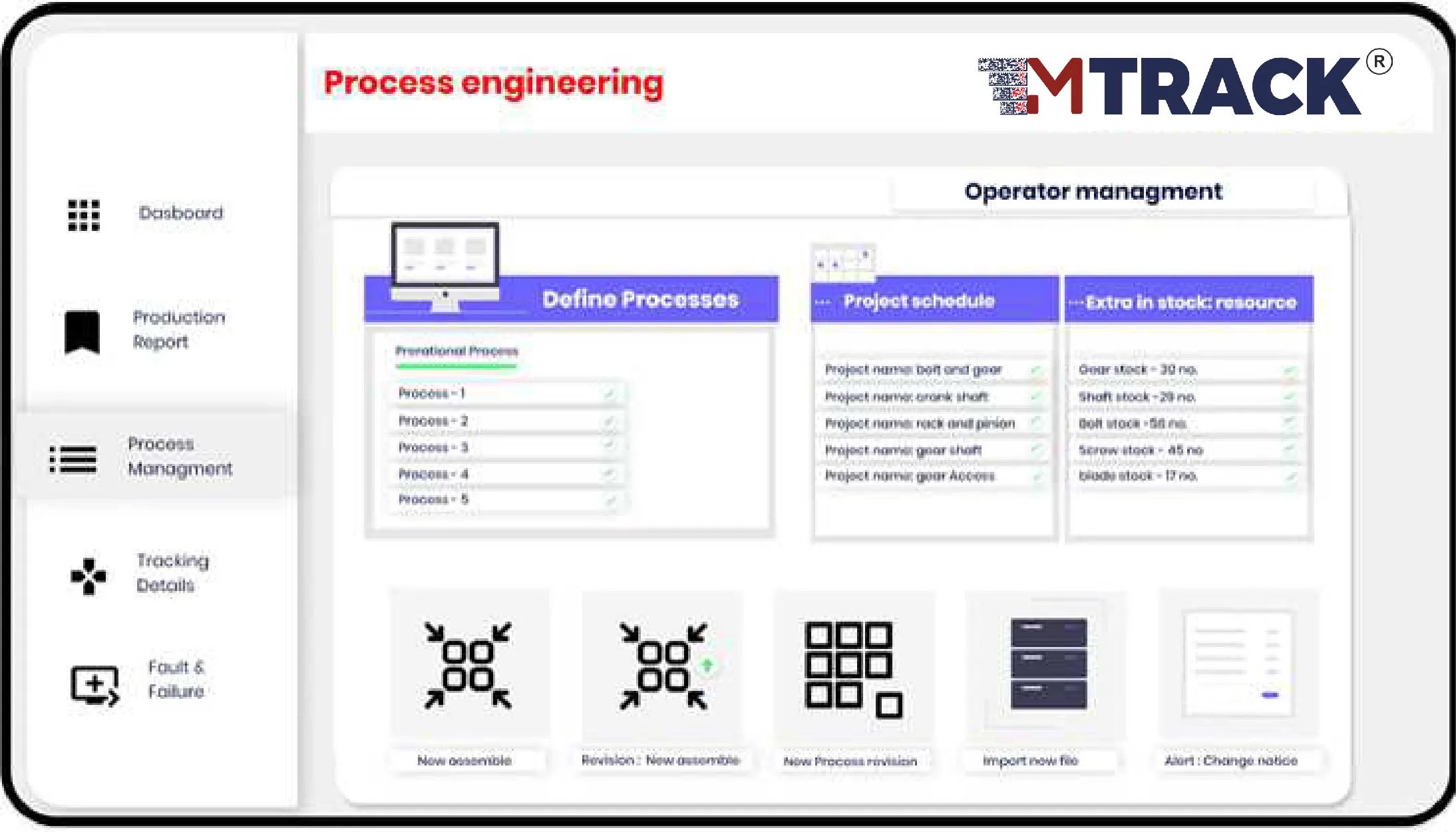

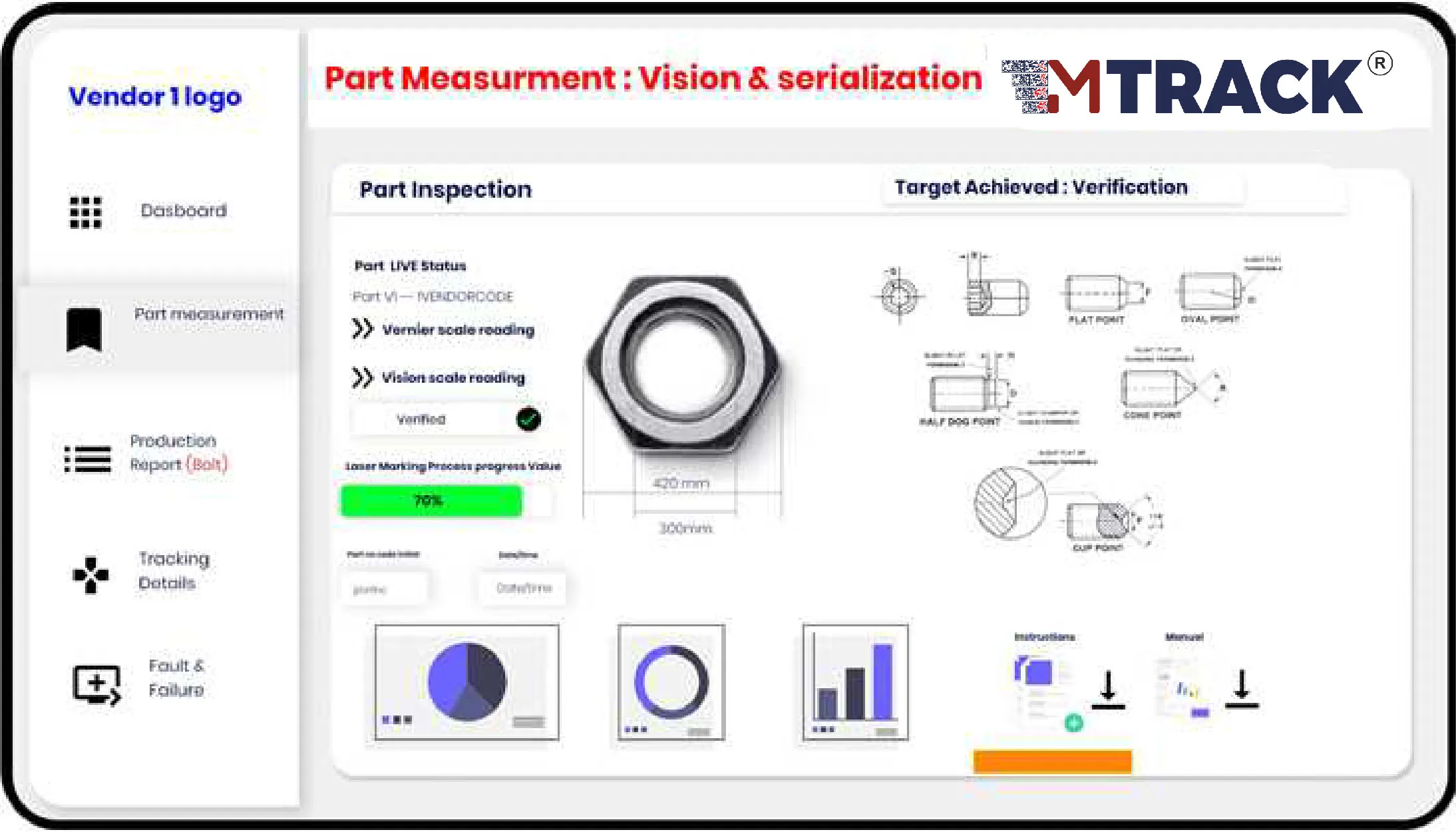

Our Smart advance MTRACK platform facilitates IIOT operations. Connects operators, smart measurement devices, and processes to make smarter decisions faster that automates the process.

Elevates the efficiency and productivity of the process

The interactive user interface speeds up the process by providing dynamic data, instruction to the operator to configure the product according to the standard rules and regulations. Furthermore, we upgrade the interface with all Modern technology and flexibility towards the ports openness.

Our MES Improves the Quality and Enterprise-Wide Compliance

It helps keep the complete record of the measurable data that is important for comprehensive quality testing and improvement. First, the raw material is purchased. Inspection of incoming raw material and its data for quality improvement. Repair, corrections needed, tests, diagnosis, and at last, the automation for corrective actions and preventive measures.

Very flexible and adaptive to the customer & business demand

Our MTrack MES system accepts command of configure-to-order. Hourly or day wish demand fluctuates. Very adaptive to the complex supply and demand. Automatically adjust with the changes.

Intelligent Supply chain management for safety and Security

Aggregation at the time of packaging and warehousing to deliver the right product to the customer in time, safe and secure. Serialization with a laser marker, barcode stick, or RFID tag helps in identifying the right product—analysis of the process and the product itself is possible with our MES(Manufacturing execution system).

Vision System integration for measurement value, Code validation, Colour and countour inspection.

Increases Uptime by keeping inventory or the stock to minimal

Implementing lean manufacturing, It is the process by which All the raw materials are managed to minimize inventory on hand, with no waste of money in stocking the raw material. And yet, lines never have the deficiency of raw material to fulfill the demand of the productions.