About Lasers

1: What is a Laser?

A laser is a high-energy light source emitted by the natural vibrations of atoms (of a gas or solid material) to cut, burn or dissolve.

What does Laser stand for?

Laser stands for Light Amplification by Stimulated Emission of Radiation

2: Laser characteristics

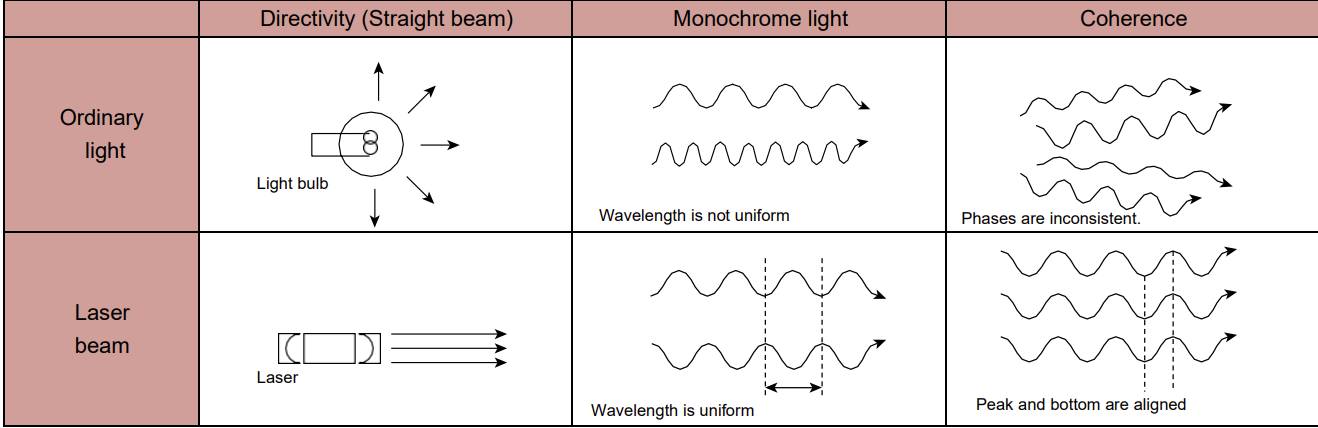

Differences between a laser and ordinary light

Unlike an ordinary light source such as a lamp, lasers provide the following features:

| Highly directional: | Laser light beam travels straight with almost no divergence. On the other hand, light from an ordinary lamp diverges in every direction. |

| Highly monochromatic: | Lasers emit a light beam with a single pure color (wavelength and frequency). An ordinary lamp emits a light beam with several colors mixed. |

| Highly coherent: | Laser provides excellent coherency (uniform phase of light relative to time) resulting in high amplitudes (higher outputs). Ordinary light produces an inconsistent phase of light with respect to time. |

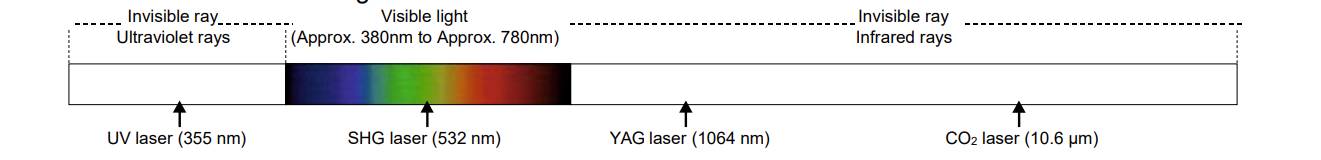

3: Laser wavelength

Laser marking equipment for industrial use

The wavelength is classified into the categories below.

- CO2 laser maker → wavelength: 10.6 µm

- YAG (YVO4) laser maker → wavelength: 1064 nm (fundamental wavelength)/532 nm (SHG)/355nm(UV)

- Fiber laser maker → wavelength: 1090 nm

YAG (YVO4) lasers and fiber lasers can be used to mark onto metal since they have shorter wavelength than CO allowing for less reflection of the laser light from the metal surface and reducing energy loss. On the other hand, CO2 lasers, which have longer wavelengths than YAG (YVO4) lasers and fiber lasers are easily absorbed by glass and plastics making them ideal for marking on transparent objects.

Laser Type

Laser Classifications

A laser can be generally classified into the following three types:

| Gas | Solid | Liquid |

| CO2* Used mainly for machining and marking applications |

YAG* Used mainly for general-purpose marking applications. | Dye Used mainly for physical and chemical applications |

| He-Ne (Helium-neon) Used mainly for measuring instruments (e.g. profile measurement). | YVO4* Used mainly for general-purpose marking applications. | |

| Ar (Argon) Used mainly for physical and chemical applications (e.g. biology). | Fiber Laser* Used for mainly general-purpose marking applications | |

| LD (Semiconductor laser) Used mainly for an excitation source and visible-light laser |

Principal medium used for a laser marker

CO2 laser

A CO2 laser is used mainly for machining and marking applications. CO2 lasers emit invisible infrared beams with a wavelength of 10.6 µm. N2 gas serves to increase the energy level of CO2, and He gas serves to stabilize the CO2 energy level.

YAG laser (Nd: YAG)/Fiber laser (Yb: Fiber)

A YAG laser and fiber laser are used for general-purpose marking applications such as marking on plastic and metal targets, as well as for machining applications. YAG lasers emit invisible near-infrared beams with a wavelength of 1064 nm, also fiber lasers emit them with wavelength of 1090 nm.

Description of YAG

YAG is a crystalline structure of Y (yttrium) A (aluminum) G (garnet). Through doping of a light-emitting element, in this case Nd (neodymium) the YAG crystal will enter the excitation state via absorption of light from a Laser Diode.

Description of fiber

Through doping of an amplifying medium, in this case Yb (Ytterbium) into the core of a quartz crystal, and pumping Laser Diode (LD) light through the fiber cable will enter an excited state and emit a 1090 nm wavelength of laser light. Laser light that is pumped through the fiber cable, even though it does not have a resonator, will be amplified while it passes further through the Yb doped core.

4: YVO4 laser(Nd:YVO4)

A YVO4 laser is used for ultra-fine marking and machining applications.

YVO4 lasers emit invisible near-infrared light with a wavelength of 1064 nm, like the YAG laser.

Description of YVO4

YVO4 is a crystalline structure of Y (yttrium) V (vanadium) O4 (oxide), or Y (yttrium) VO4 (vanadate). Through doping of a light-emitting element, in this case Nd (neodymium) the YVO4 crystal will enter the excitation state via absorption of light from a Laser Diode.

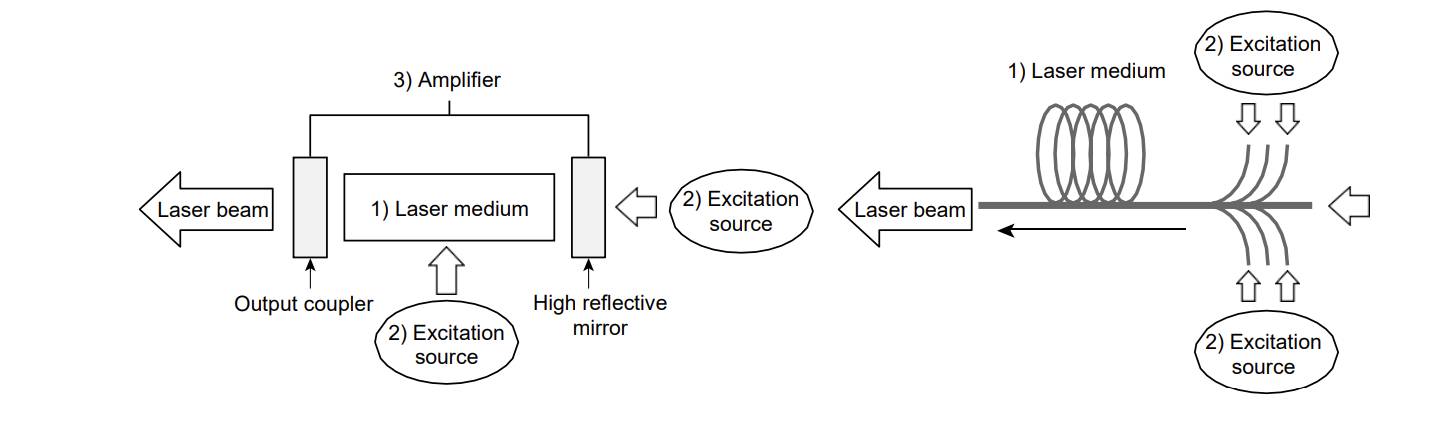

Laser Oscillation Tube Elements

Three elements of a laser oscillation tube

Three types of MARKOLASER laser markers

| Torque Coding & Marking Laser 10W Torque 30W Torque 70W Torque |

3D Markolaser Series 20W / 30W / 50W / 70W Orion Series Minnie Series Ursa Series Hercules Series |

2D Markolaser Series 20W / 30W / 50W / 70W Orion Series Minnie Series Ursa Series Hercules Series |

|

| 1) Laser medium | CO2 (gas) | YVO4 (solid) | Fiber |

| 2) Excitation source | Electric discharge | Light (LD) | |

| 3) Amplifier | Optical resonator | Fiber length | |

Laser Oscillation Operating Principle

- When an atom (molecule) absorbs external energy, it shifts from a low energy level (ground state) to a high energy level. This state is called the excited state.

- When the excited state is unstable, and the atom (molecule) will return to a lower energy level. This is called transition.

- During transition, the atom (molecule) emits light corresponding to the energy difference. This phenomenon is called spontaneous emission.

- The emitted light collides against other atoms during the excited state, causing induced transition. Emission of induced light is called induced emission.

.jpg)

Laser Safety Standards

1: Global safety standards

|

|

||||||||

2: About 2014/35/EU & 2006/42/EC

Description of CE Complaint

CE-compliant meet the essential safety and health requirements of the EC Machinery Directive 2006/42/EC. Here you will find an overview of machine-specific safety and protection devices, which make our lasers one of the safest in their class all over the world.

Description of laser safety standard - ISO 45001:2018

This is to certify that Occupational Health and Safety Management System in accordance with standard’s clauses is established and being implemented.

Description of laser safety standard - ISO 14001:2015

his is to certify that Environmental Management System in accordance with standard’s clauses is established and being implemented.

3: About IEC 60825-1

Description of IEC

The IEC (International Electrotechnical Commission) is an international organization that prepares and publishes standards for all electrical, electronic, and related technologies.

Description of laser safety standard

IEC established an international standard "IEC 60825-1" for laser products, which serves as a common safety standard for IEC member countries.

4: About FDA (CDRH)

Description of FDA

The FDA (Food and Drug Administration) is a branch of the HHS (Department of Health and Human Services). The CDRH (Center for Device and Radiological Health), a division under the FDA, conducts administrative operations of radiological regulations. For production, sale and distribution of laser products in the U.S., manufacturers must comply with the requirements of these regulations.

Description of the laser safety standard

Title 21 "Radiological Health" of the CFR (Code of Federal Regulations) stipulates regulations on radiation (including lasers) as well as general rules.

Functional Safety Standards

ISO 13849-1 provides safety requirements and guidance on the principles for the design and integration of safety-related parts of control systems, including the design of software. Based on idea of “Functional Safety”, it regulates mechanical safety according to functions and reliability. ISO 13849-1 was revised based on the conventional standard EN 954-1 by adding details from IEC 61508 (IEC 62061), which defined functional safety.

.jpg)

.jpg)

.jpg)

Laser Safety Measures

1: General laser safety

Purpose

The purpose of laser safety standards is to prevent laser related injuries. Safety protection against lasers can be attained when users correctly recognize the potential hazards of laser products and correctly perform specific procedures using safety functions of the laser products.

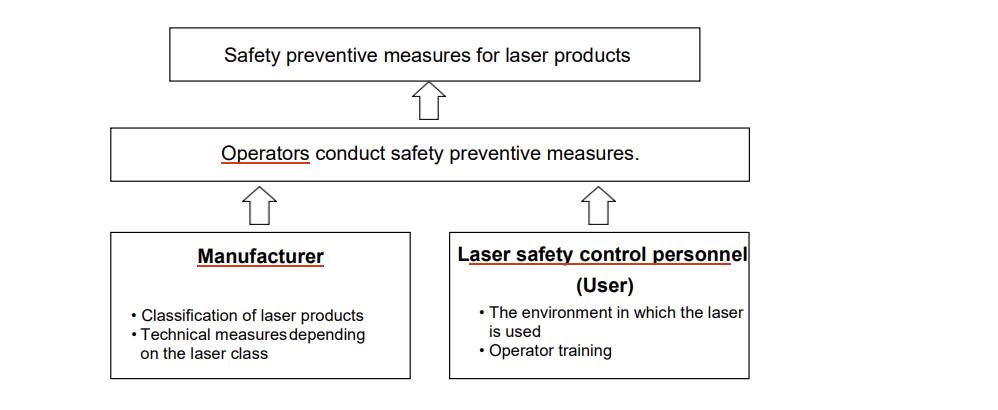

2: Laser safety preventive measures

About laser safety preventive measures

People involved with laser products are manufacturers and users. Furthermore, users are

classified into laser safety control personnel and operators.

An outline of safety measures required for individuals is as follows:

Description in respect to preventive safety measures for end users:

1. Maintaining Optimum environmental conditions including but not limited to:

a. Climatic Conditions (e.g., temperature, relative humidity); 25 °C is normal room temperature and is

intended to provide a common reference that can be used for machine operating conditions

b. Dust free environment: controlling the environment in which beam path components are located (in

particular, preventing particulate matter and/or condensation from collecting on laser irradiated

surfaces of beam path components)

Laser Product Classifications

Based on the laser safety requirements specified in IEC60825-1 and FDA(CDRH) 21CFR Part 1040.10, these products are classified as Class 4/ Class IV Laser Product.

IEC standard

| Laser class | Class Definition |

| Class 1 | Laser products that are safe during use, including long-term direct intrabeam viewing, even when exposure occurs while using telescopic optics. |

| Class 1M | Laser products that are safe, including long-term direct intrabeam viewing for the naked eye

(unaided eye). Eye injury may occur when exposure occurs while using telescopic optics such as binoculars. The wavelength region for Class 1M lasers is restricted to between 302.5 nm .4,000 nm |

| Class 1C | Laser products that are intended for direct application of laser radiation to the skin or internal body tissues for medical, diagnostic, therapeutic or cosmetic procedures such as hair removal, skin wrinkle reduction, acne reduction. |

| Class 2 | Ltoaser products that emit visible radiation in the wavelength range from 400 nm 700 nm staring into the beam. The use of optical instruments does not increase the risk of ocular injury. |

| Class 2M | Laser products that emit visible laser beams and are safe for short time exposure only for the naked (unaided) eye. Eye injury may occur when exposure occurs while using telescopic optics such as binoculars |

| Class 3R | Laser products that are potentially hazardous but the risk of injury in most cases is relatively

low. The risk of injury increases with exposure duration, and exposure may be hazardous for intentional direct intrabeam viewing. |

| Class 3B | Laser products that are normally hazardous when intrabeam ocular exposure occurs including accidental short time exposure. Viewing diffuse reflections is normally safe. |

| Class 4 | Laser products for which intrabeam viewing and skin exposure is hazardous and for which the viewing of diffuse reflections may be hazardous. These lasers also often represent a fire hazard. |

IEC standard

| Laser class | Class Definition |

| Class I | Class I levels of laser radiation are not considered to be hazardous. |

| Class IIa | Class IIa levels of laser radiation are not considered to be hazardous if viewed for any period of time less than or equal to 1x103 seconds but are considered to be a chronic viewing hazard for any period of time greater than 1x103 seconds. |

| Class II | Class II levels of laser radiation are considered to be a chronic viewing hazard. |

| Class IIIa | Class IIIa levels of laser radiation are considered to be, depending upon the irradiance, either an acute intrabeam viewing hazard or chronic viewing hazard, and an acute viewing hazard if viewed directly with optical instruments. |

| Class IIIb | Class IIIb levels of laser radiation are considered to be an acute hazard to the skin and eyes from direct radiation. |

| Class IV | Class IV levels of laser radiation are considered to be an acute hazard to the skin and eyes from direct and scattered radiation. |

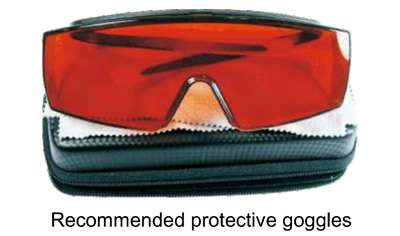

Eye protection

In the controlled area in which the laser product is installed, wear protective eye goggles, regardless of whether normal use or maintenance, in case of accidental exposure to laser emission.

Protective goggles

Select protective goggles that are appropriate for the laser light wavelength.

- CO2 laser (wavelength: 10.6 μm, OD: 5-7) (ML-G9300/ML-Z9500/ML-Z9600 Series)

- YVO4 laser (wavelength: 1064 nm, OD: 5-7) (MD-V9900/MD-X1000 and 1500 Series)

- SHG laser (wavelength: 532 nm, OD: 4-7) (MD-T1000 Series)

- UV laser (wavelength: 355 nm, OD: 6 or more ) The laser emission warning can be confirmed. (MD-U1000 Series)

- Fiber laser (wavelength: 1090 nm, OD: 6 or more ) The laser emission warning can be confirmed. (MD-F3000, 3100, 5100, 3200, 5200 Series)

Acrylic filter

Laser lights can be blocked by attaching the acrylic filter to the monitoring window on the equipment, the protective

enclosure, or the observation window on the protective cover

Note: Protective goggles are intended to protect eyes from scattered light. Never use protective goggles against exposure to direct or reflected

light.

Local ventilation system

If poisonous gas is generated during laser marking on a target object, identify the substances produced by the gas and provide a local ventilation system

Appointing a laser safety officer

Appoint a safety officer who has knowledge and experience in handling laser products in order to enforce safety management. The responsibilities of the Laser Safety Officer are as follows:

- Suggesting prevention measures related to laser emission

- Setting up the laser controlled area (area in which there is a risk of exposure to laser emission from the laser products)

- Managing the key for the key-operated power switch

- Checking the protective equipment and its use

- Training for operators

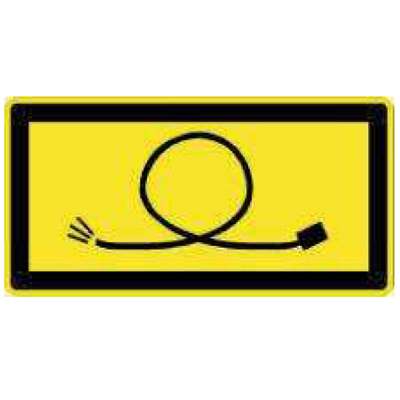

Warning labels

|

This symbol is to alert the user to the danger to exposure of hazardous invisible laser radiation |

|

This symbol is to emphasize important information regarding installation points or operating procedures |

|

Warning Labels |

|

Warning Labels |

|

Warning Labels |

|

Optical Fiber |

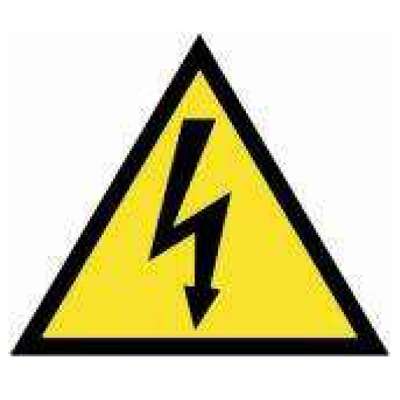

|

Electrical Hazard Labels |

User's Guide

Take safety measures for class 4 laser products

Use of Remote interlock (Emergency stop) input terminal

Connect the remote interlock (emergency stop) input terminal (remote interlock connector) of the laser system to emergency stop switches or the like to prevent laser radiation in an emergency

Key operated power switch (Key control)

To prevent operation of the laser system by unauthorized users, the key should be managed by the Laser Safety Officer

Setting the warning indication sign and controlled area

Post a warning sign at the entrance to the area in which the laser product is installed in order to ensure that workers and outsiders are informed about the dangers.

Termination of beam path

Installation must be performed so that it reduces the possibility of unintentional laser radiation on any object including a marking target, a machine or part of a machine, for normal and foreseeable fault conditions. To avoid eye or skin exposure to direct or scattered laser radiation under these conditions, the laser beam emitted by the laser system must be terminated at the end of its useful path by a diffusely reflecting material of appropriate reflectivity and thermal properties or by absorbers.

Protective clothing

If skin is exposed to a laser beam reflected on a marking target in a control area where a laser product is installed, it will cause skin to burn, and clothes may catch fire. During laser operation, wear flame-resistant clothes and protect the skin as much as possible

Safety Precautions

Warning

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. Follow the instructions mentioned in this manual. Otherwise, injury to the human body (eyes and skin) may result.

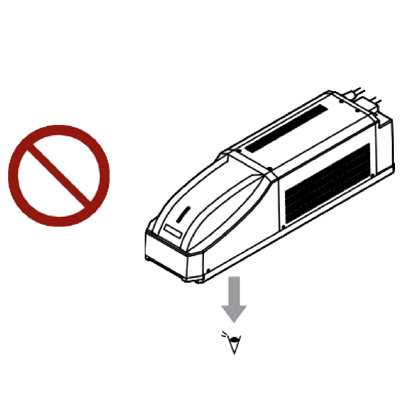

The following example is for 2D Markolaser Series. For other series, refer to the appropriate user’s manual.

| 1 | Do not expose eyes to laser radiation or diffuse

reflection. Exposing eyes to laser radiation or diffuse reflection may cause blindness. |

|

| 2 | Do not expose skin to laser radiation or diffuse reflection. Be careful that you do not insert a hand or other body part into the marking area during operation. Doing so may cause damage to skin, such as burns. |

|

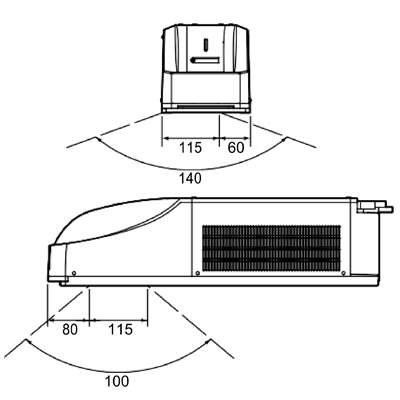

| 3 | While the laser radiation emission warning lights, the area from the center of the window shown below is the hazardous area to which the laser will be emitted. If a part of body or an object catching fire enters this 115 60 range, eyes or skin may be damaged or fire may be 140 caused. Considering the hazardous characteristic of this range, make sure to cover with an enclosure which has appropriate reflectance and heat characteristic. |

|

| 4 | Terminating the beam path. To avoid eye or skin exposure to direct or scattered laser radiation, the laser beam emitted by the 2D Markolaser Series must be terminated at the end of its useful path by a diffusely reflecting material of appropriate reflectivity and thermal properties or by absorbers. | |

| 5 | While the laser radiation emission warning lights, the area from the center of the window shown below is the hazardous area to which the laser will be emitted. If a part of body or an object catching fire enters this 115 60 range, eyes or skin may be damaged or fire may be 140 caused. Considering the hazardous characteristic of this range, make sure to cover with an enclosure which has appropriate reflectance and heat characteristic. |

|

| 6 | Do not disassemble the 2D Markolaser Series. Otherwise exposure to laser radiation and electric shock may result. The 2D Markolaser Series is not under warranty and cannot be repaired if it has been disassembled. |

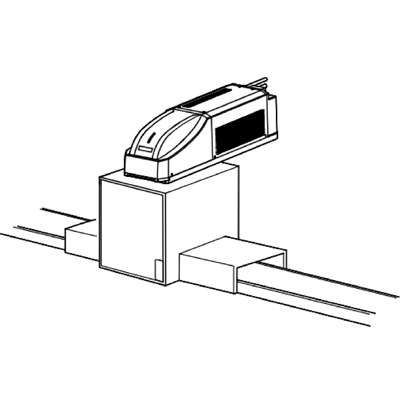

|

| 7 | Enclose the area to which the laser will be emitted with protective housing. The protective housing, which has properreflectance andthermalcharacteristics,shallbeinstalledtoprevent human access to laser beam reflected from the target for marking or the surrounding objects. Install the 2D Markolaser series so that the path of the laser beam is not as the same height as that of human eyes. |

|

| 8 | Be sure to turn off the laser emission and wear protective eye goggles before performing maintenance tasks such as cleaning the window surface. Otherwise exposure to unintentional laser radiation may result. |

.jpg)

|

| 9 | Do not use the 2D Markolaser Series near flammable materials. Do not place any flammable objects or gas (organic solvents) near the beam path of the marking laser. This may cause a fire. |

|

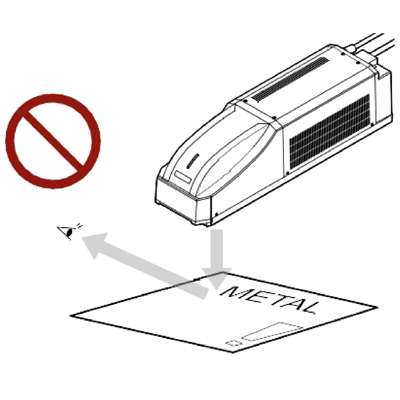

| 10 | Do not irradiate the laser beam onto mirrored metal materials. The CO2 laser cannot mark metal materials. Never attempt to mark highly reflective metal materials. |

|

| 11 | ZnSe (zinc selenium) is used for the window and other optical parts. ZnSe is treated as a poison by law. Rely on a company that handles industrial waste when disposing of the product. | |

| 12 | Turn off all power before connecting the controller power cable. Otherwise, it may cause an electric shock. | |

| 13 | Do not use the 2D Markolaser Series in any way other than that described in this manual. Otherwise exposure to unintentional laser radiation may result. | |

| 14 | Do not use this product in the state with external damage | |

Laser Safety Precautions

This standard describes principal terms concerning laser products and safety when using laser products.

Diffuse reflection

The change of the spatial distribution of a beam of radiation by scattering in many directions by a surface or medium.

Specular reflection

The reflection from a surface that can be considered a beam, including reflections from mirrored surfaces.

Nominal Ocular Hazard Distance (NOHD)

The distance from the laser aperture at which the radiant exposure equals the maximum permissible exposure (MPE) of the eye. Since a laser beam has a divergent angle, the laser beam spot diameter becomes larger as the distance from the laser source becomes longer. As a result, the energy applied in a unit area is reduced.

Nominal Ocular Hazard Area

The area within which the beam irradiance or radiant exposure exceeds the appropriate corneal maximum permissible exposure (MPE)

Maximum permissible exposure (MPE)

The level of laser radiation to which, under normal circumstances, persons may be exposed without suffering adverse effects.

Accessible Emission Limit (AEL)

The maximum accessible emission permitted within a particular laser class.

Effects of a laser beam on the human body

Harmful effects

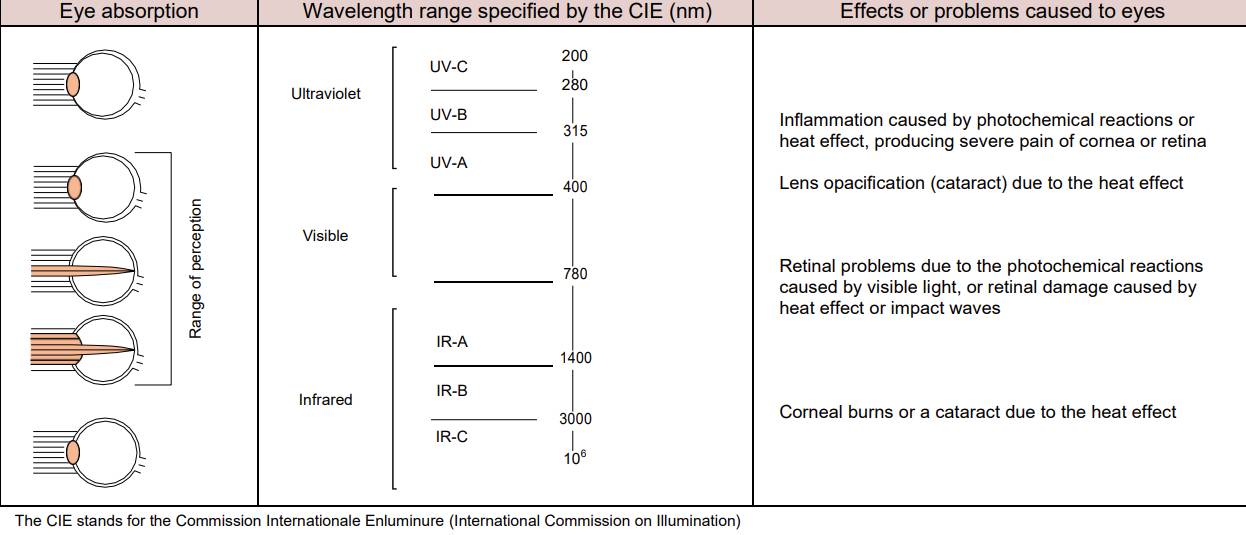

If a human body is exposed to a laser beam, denaturation of protein due to the heat effect, photochemical reactions in cell tissues or tissue destruction caused by impact waves (plasma flow and resulting pressure waves) may occur. The biological effects depend on the wavelength, output, and output waveform (continuous wave or pulse wave) of the laser beam, but in general, it is more likely to cause serious, irreversible damage to the eyes rather than to the skin. Besides the direct biological effects of a laser beam, attention should be paid to secondary problems caused by the release of harmful substances generated by a laser beam irradiating processing targets or other objects around the laser marker.

Eye problems

An argon laser, YAG laser or CO2 laser, which all radiate continuous or long pulse waves, cause the following problems due to the heat effect or photochemical reactions:

1. Laser beams whose wavelength is out of the range of perception (ultraviolet (200 to 400 nm) and near-infrared (1,400 to 106 nm)) are absorbed in the tissues of cornea or lenses, causing a cataract with corneal burns or visual degradation

2. Laser beams whose wavelength is within the range of perception (visible (400 to 780 nm) and near-infrared (780 to 1,400 nm)) are focused on the retina because of the eye’s optical systems (cornea and lens) and the density becomes approximately 105 times greater. This causes the following problems.

Laser beams that produce continuous waves are absorbed in the retina (center or vicinity) and mainly cause retinal burns due to the heat effect

Visual lasers with a wavelength of approximately 430 nm, which is absorbed in the visual pigments of retinal photoreceptors, mainly cause retinal problems due to photochemical reactions.

YAG/YVO4 (Q-switch) lasers or CO2 lasers, which have a short pulse and high peak power, cause retinal burns or fundal hemorrhage, often resulting in severe visual degradation.

3: Skin problems

If a human body is excessively exposed to a high-power laser beam, changes from mild erythema, blister formation to carbonization occur.

According to a notice issued by the CDRC on preventative measures against problems caused by a laser beam