Laser Marking on Plastic, white goods, and Household appliance

Almost every part of our life, at home, at work, and at play, are powered by electricity. And where there is power, there are also plastics. We wouldn't be without the labor-saving equipment in the kitchen, such as washing machines, microwave ovens, and kettles.

White Plastics products include:

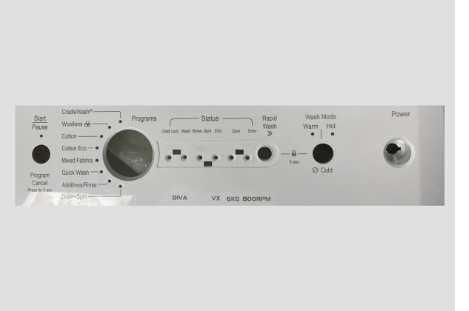

- Sanitary and appealing knobs, handles, and door facings for cookers.

- Liners, handles, internal fittings, and panels for refrigerators and freezers.

- Housing panels for washing machines and dishwashers.

What is the significance of Substrate and how it effect the quality of laser marking?

'Plastics' refers to materials having significantly varying chemical compositions, which means that the procedures used to treat them, such as laser marking, provide wildly varying results.

Polycarbonate, polyamide, polyester, PE, PET, ABS, and various other polymers are just a few examples. These factors influence the wavelength of the laser that should be used.

Every plastic has its laser marking and processing wavelength requirements.

- For example, PET plastic requires a laser marking machine with a very short wavelength of around 9.45 μm. The Co2 Laser marking machine is a suitable laser marker for Creating an eligible mark on PET plastics. If the wrong wavelength laser marker is employed to mark the plastics, that may lead to burns and micro holes.

- On this semi-transparent material, laser marking produces white symbols that appear to float on the surface. Laser marks with the necessary specifications are always clear and sharp, from PET bottles to thin-film materials.

- We can now mark all sorts of suitable white plastics, thanks to the laser sources and the significant specialization of contemporary laser technology. However, the reactions caused by color pigments and other additions vary greatly.

- Marking MRP, date, codes, logos, and graphics on plastic components is common practice. Laser marking is preferred over other methods present in the market. Ink adherence, dark substrate contrast, and finish complexity are not issues with laser marking as they are with ink-jet.

How Markolaser Help Household appliance companies?

Laser etching on some plastics may be challenging. Different contrast levels can be achieved depending on the kind of plastic and the laser settings used during the laser marking process.

The laser must only melt or burn the surface layer of ABS plastic to create optimal contrast. Foaming is a term used to describe this type of laser engraving.

It is accomplished by lowering the laser's power, using a low frequency, and scanning at afast rate. The material would simply melt if the laser utilise too much power or had too high a frequency since the laser would create too much heat.

For the last two decades, we are providing laser marking solutions for:

- High productivity to Mark consistently on Household appliances

- Colored laser marking on Metals for Premium Marking and looks

- Black laser marking on Metal and Plastic for durability

- Laser Marking with ease on non-linear and curve geometries

- The precision of complex drawings

- Abrasion resistance Marking with no burr

Laser black marking on plastic

Laser black marking on metal

Laser foaming on dark product

What are the Benefits over the printing screen printing and pad printing machine

- It saves time : 1. It saves time : Pad printing machine requires many consumables like pad printing pad, Pad printing inks, Plate for pad printing machine, again, a laser marking machine.

The screen printing machine requires screen printing mesh and inks.

The laser marker doesn't require any consumables such as inks, pads. The Fiber laser marker has 100000 hours of expected laser lifetime. - Safe and environmental friendly:

From the standpoint of environmental safety, the laser is the best technical option.

With no chemical discharge and the fumes from the laser marking are not harmful. Inks may contain hazardous chemicals.

We provide a laser fume extractor with a laser machine to extract all the fumes while laser marking. Burr and debris are some of the waste that is easy to filter. We don't use any additional components because the laser is a DPM (Direct Part Marking) technology. - Custom flexible software:

Laser marking software (Markomark software) accepts all types of data. Our laser

marking software accept dynamic data such as any graphics that are 2D or 3D file for

marking & engraving on 2d and 3D surface.

Our Laser marking software has the capability to generate dynamic alphanumeric data. It automatically generates serial numbers in a sequence. It gives the utmost flexibility in changing graphics. - Resistance: Prints and labels deteriorate, and codes and text become illegible. It is a concern in terms of productivity and corporate image. Laser marking, on the other hand, is entirely irreversible over time. A permanent marking on the substrate is the best option for printing on these white goods.

What are the benefits of using Markolaser Laser marking machine?

- Flexible laser marking: A variety of wavelengths, powers, and characteristics is helpful to fine-tune lasers to the specific material.

- Gentle marking with no adverse effect on substrate: The component surface is practically unaffected by cold and non-contact laser marking.

- Premium quality marking: Even the most complex markings are highcontrast, crisp, and smudge-free, thanks to the laser.

- Permanent and high definition laser marking: Laser inscriptions on polymers do not fade or wear off, and they are completely legible even after years of use.

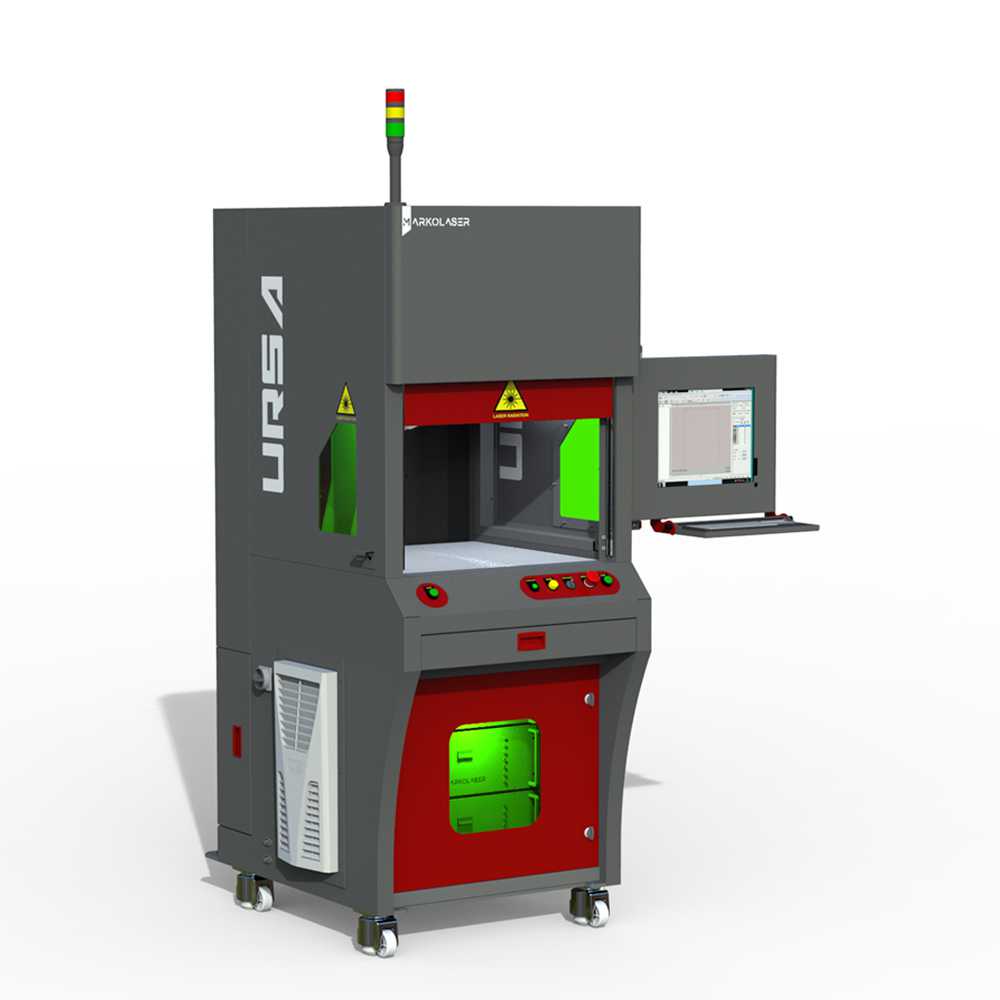

Markolaser Laser Marking machine

We develop and create a better aesthetic with Fiber laser.

In especially for electronic and home appliances and other household applications, the aesthetic outcome of marking is critical, necessitating the employment of a laser that produces a high-contrast black. A fiber laser with extremely short pulses is ideal for this application, delivering an impalpable annealing effect.

Laser Foaming

A low-intensity power laser marking creates a white foam on a dark substrate. The Household electronics appliance such as a mixture, grinder, and oven comes in the black and dark plastic. On these substrates, Laser Foaming becomes a blessing.

Annealing is the process of applying long-lasting marks on metal using a laser.

Annealing is a well-known technique for permanently branding on steel and metal washing machine panels. It is because when heated with a laser, certain materials take on annealing hues. The temperature at which the metal is heated has a big impact on marking quality.

It is due to the formation of an oxide coating on the surface during laser annealing, which has qualities that control the color impression.

The fundamental benefit of Laser annealing is that the surface is entirely intact, and the marking is easily readable, long-lasting, and abrasion-resistant. Wherever a precise fit is required or material bulging is banned, annealing is the best option. As a result, this method is appropriate for consumer items like kitchen utensils, household appliances, or medical devices.

Why Markolaser for Laser marking and smart factory solution

One stop solution

We are the sole supplier of Laser marking machine, data management Software and automations

Open port and flexible

Software and hardware flexibility :

Ether net , profinet etc

Easy to integrate with database

the flexibility to integrate with any type of database like sap, oracle, amazon web services etc

Industyr 4.0

We will help you automate you process. with minimal intervention of the human or no intervenion

Flexible with Vision system

We will help you integrate the vision system in the machine. Which helps inspection the quality of marking

Laser Marking system

We are the manufacturer of premium

industrial laser