Laser Engraving on Automotive Parts for Traceability and Serialization: Logo Marking, Backlit Laser, paint removal for Interior Decoration and Data matrix (DPM) on metals

Effective permanent marking with automated solution

Markolaser's automotive direct part marking and traceability solutions meet all ISO/IEC requirements as specified in the rules of ISO/IEC TR29158, ISO/IEC TR24720 & ISO 16022 Identification Standard and Direct Part Marking Guidelines.

Monitoring and controlling the process

The Markolaser real-time online tracking system helps save lead times and optimize supply chains by updating information about operations happening in different zones at the same time. By using data management systems, you can visualize the ongoing processes and identify the right produce. When, where, and by whom within a particular process will help you identify the right problem.

Implementing Traceability Poka-Yoke

An error proofing process improves the quality of a product by ensuring that the right product is placed in the right sequence and right processes are carried out on it. The code is scanned to reduce errors due to manual data feeding . This takes café of liability, warranty issues and safety, to fulfil regulations & to identify exactly the right part which is subjected to theft and counterfeit.

Markolaser's laser marking solutions keep all parts in the automotive industry fully tracked and traced in a complete supply chain of manufacturing process thought out the life cycle with the help of a full range of cost-effective technologies.

Our 24*7 service culture and our ‘customer is our partner ‘philosophy delivers the comprehensive support you need to keep your production efficient.

Markolsaser delivers traceability systems for automotive components including castings, forgings, plastics and rubber in assembly and supplier production facilities.

-

Surface marking on automotive metal components

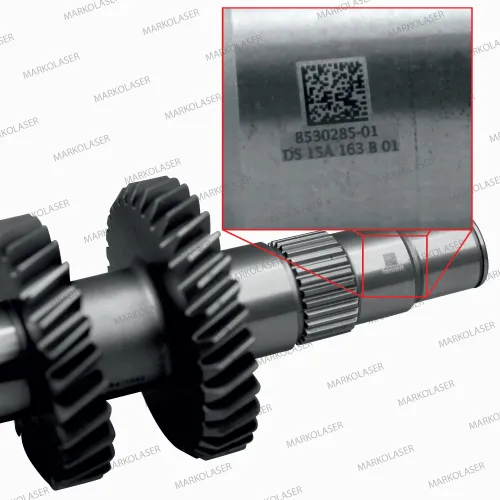

Laser marking of data matrix code on gear

With our Fiber Lasers, we are able to surface mark Data Matrix code (2D-code) onto metal components such as gears. For added uniqueness, the code is encoded with a unique identification number. With this ID, the gear can be traced from start to end in the supply chain. Laser Marking of Data Matrix code follows guidelines defined by ISO-16022 which is an international standard for “Data Matrix Bar-code Symbology Specification.Using Cognex made Industrial Bar-code Scanner, verifying and validating (with respect to AIM-DPM-1-2006 or ISO/IEC TR 29158) of laser marking and encoded data respectively could be performed

-

Surface marking on automotive metal components

Direct part marking (intrusive marking) of data matrix code on transmission shaft

If a component has a deeply recessed data matrix code, then it's sometimes difficult to read the code. Sometimes part marking (intrusive marking) is necessary in order to make the code easier to identify. With Direct Part Marking, a permanent mark is created on the component by changing its surface properties. The typical choice is a rectangular data matrix code instead of a square data matrix code. Since this option relies on Direct Part Marking, it will be identified throughout the life span of the component.

-

Surface marking on automotive metal components

Marking of final assembly code on automotive gear assemblies

Our Fiber Lasers are easily integrated into the assembly drive line, where every part of the gear assembly is made unique by marking the data matrix code with a unique identification number. This allows us to prevent the intermixing of components at the final assembly stage by poka-yoke with the help of our Traceability software.

Alarms are provided if any wrong part is assembled in the final assembly. A final assembly code is given to the gear assembly, which contains information of every part assembled for future analysis.

-

Surface marking on automotive metal components

Serial number marking on bearings

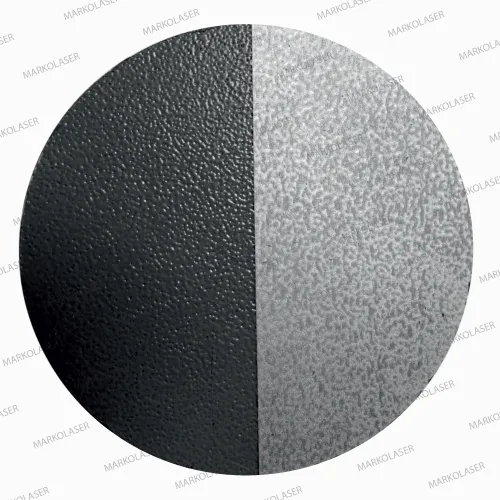

High contrast Black marking of serial number on the circumference of bearings is done with the help of our fine laser systems. These marks are corrosion resistant as there is no iron present in the mark, which in turn increases the mark durability. This laser marked serial number can withstand harsh environments such as high working temperature zones, friction resistant and many more.

The Serial Number present on the bearing contains information such as warranty period, manufacturing date etc. The serial number marking by laser thus reduces the warranty costs claimed by the customer.

-

Laser engraving of 2d-code on casted automotive component

Data matrix codes are engraved on casted components with high surface roughness using high energy laser engravers. Despite washing or oiling, these engraved data matrix codes can still be read. In order to determine the size of the Data Matrix, it is important to know the component's surface roughness. Using the ISO/IEC 16022 data, it is possible to determine the minimum cell size for a Data Matrix code.

-

Surface cleaning of automotive components by laser.

A high level of performance is required from every component in the automotive industry. Rust is one factor altering the performance of the components. Our specialized laser for surface cleaning allows us to remove the topmost layer of the material only to a few microns deep without altering its properties.

-

Paint removal by laser

Backlit- Day & Night

The day-night-marking is done by removing the coated layer. The individual coat layers are removed with great precision, so that backlit become visible to us.

This is only possible with the help of our laser marking process . An injection mold can be used for the most diverse switches or control elements.

The low tool price associated with huge volumes and the high flexibility with regard to the marking contents make the process of laser marking more effective

Turnkey Automated solution

We have a standard machine for Traceability automated solutions. If our machine does not fit your requirement, we can customize the solution to the exact specifications your project requires.

Do you have a problem? We have a solution. We develop a complete process according to your specified project requirements. We have worked with some of biggest players in the automotive industry by creating designs for customized applications that fit their exact needs.

Simple and easy Integration

The simplest and effortless way to integrate laser marking and automation with full traceability into your manufacturing processes is made easy with EtherNet/IP, Rs232, Ethercat, Profinet, Profibus OPC UA, Modbus communication,

Great Quality & speed

Markolaser's machines mark on a variety of surfaces and parts of all different shapes and sizes. Whether it is a 2D data-matrix or bar-code or serial number, we can keep your

Service and support

Our support team provides around-the-clock coverage, making sure that your business keeps running smoothly.

Importance of Serialization and traceability in automotive Industry.

In 2022, Automotive manufacturers talked about Tracing and tracking of all Automotive Parts. Product traceability of the individual part has become an important factor in the automotive industry. Individual parts are assembled in one assembly which is again given a unique assembly number to trace the complete gear assembly.

Every line in the automotive industry requires Serialization because of warranty issues and break downs.

Automotive manufacturers and OEMs are subject to recalls. These recalls have not only hurt the reputation of companies, but they've also lead to a huge loss of economy. For example, take a look at Toyota or Maruti.

Markolaser is helping those automotive companies by providing Automatic Laser Engravers and Software solutions for them to keep track of the data for the entire assemble from individual bolt.

A company needs markers which can withstand a harsh environment otherwise the quality will be effected due to wear and tear.

A high speed production line needs a technologically advanced system so that it can be in sync with the present system. This enhances production efficiency. This article will show you how the implementation of traceability systems on your production line can improve efficiency with some examples.

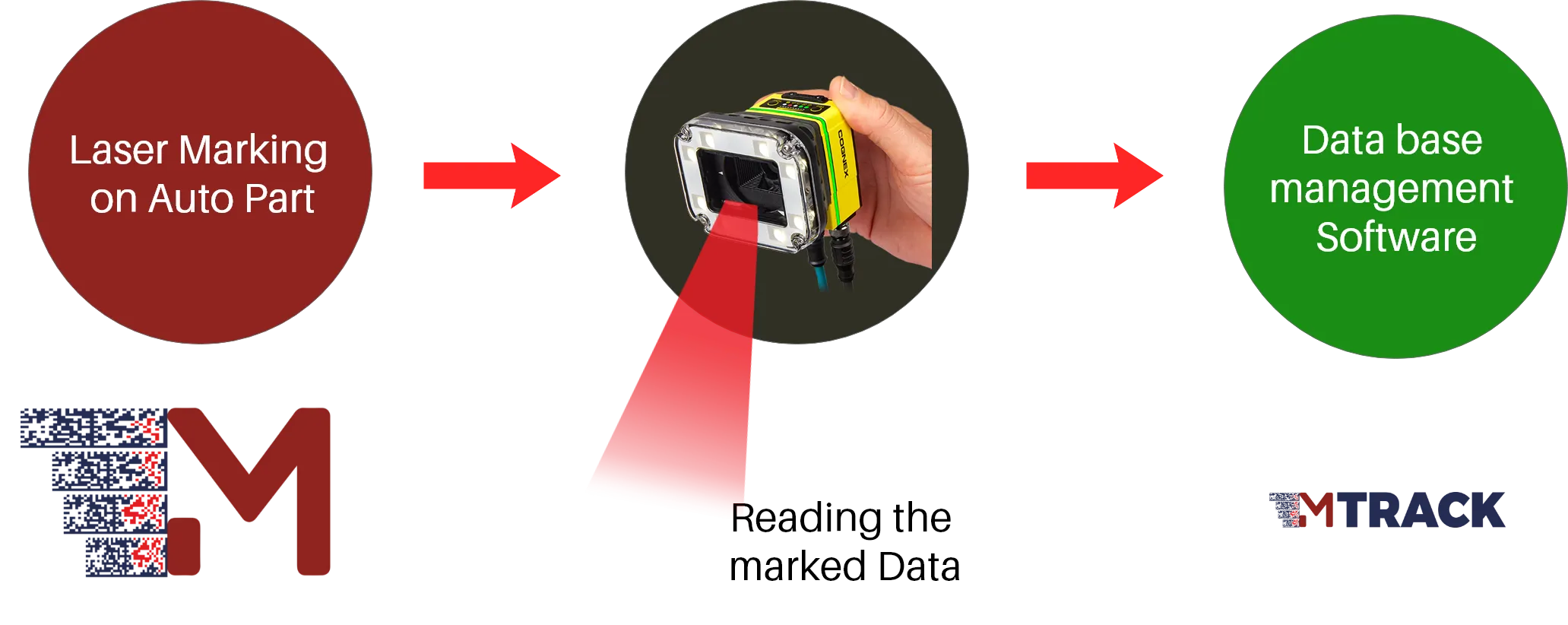

Our Laser Engraver for traceability is integrated with built in Vision Camera

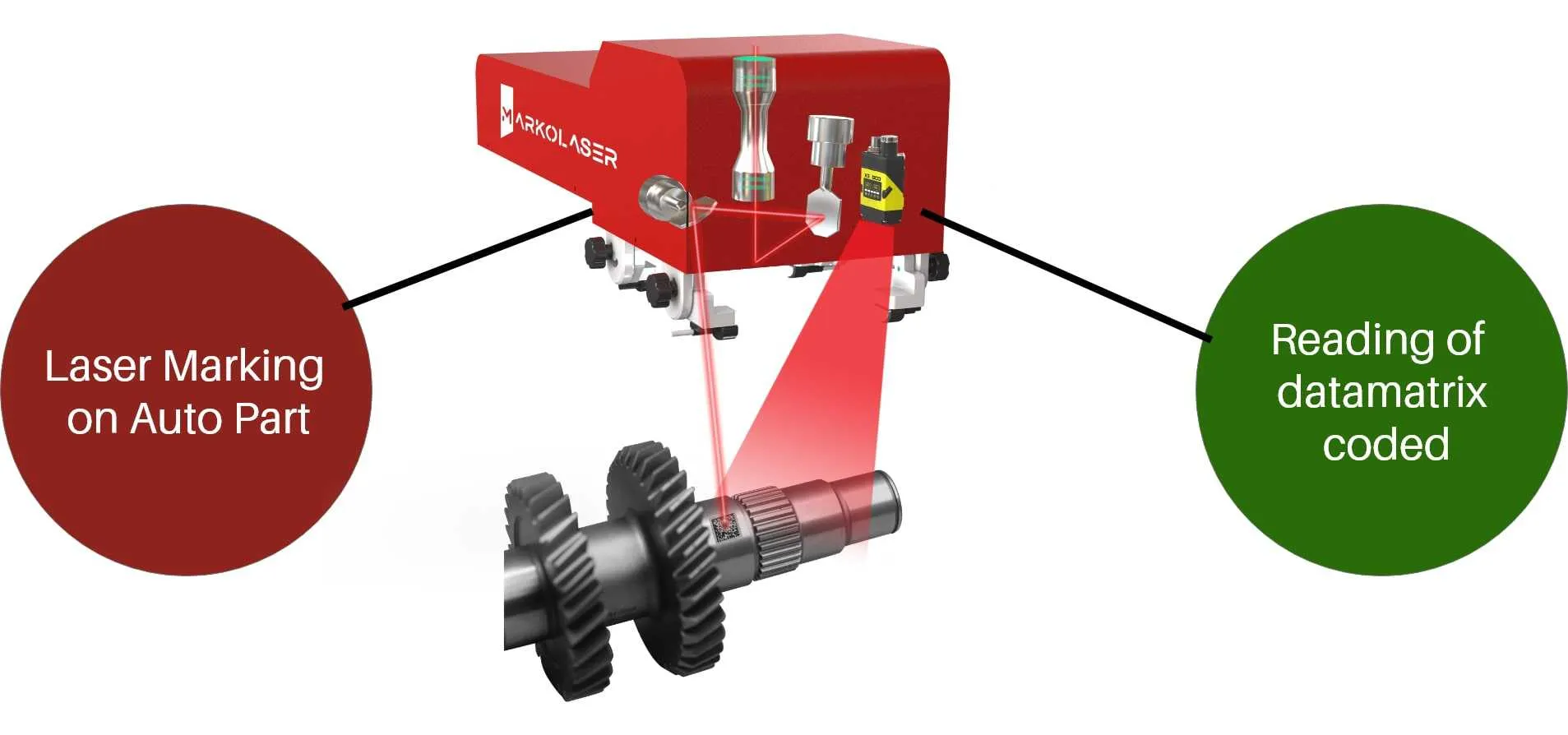

1. 1. THE Markotracer Model for Automotive Manufacturers and equipment manufacturers is integrated with a Smart Code reader to check the quality of Marking on automotive components. A 2D code reader inside the Laser marking head needs a light for the right exposure, so that the camera can read the code and check the quality of the Datamatrix code that is engraved on the automotive part (such as a gear assembly in our case.) The Marking and the reading happens simultaneously, completing the process and making it economical in terms of time and money.

Right Judgment of Laser Marking Quality:

The Vision 2D Code reading camera helps in Validating Quality - meaning the Grade of the code which is engraved on the Automotive part. The Data matix is the only code allowed to mark on auto metal parts according to the traceability code standards. ISO standards such as ISO/IEC TR 29185 define that the Code will stay longer (i.e readable or not) The code will help us in taking the right decision whether the auto part must move into a production cycle or no, because once a defective part goes into the production cycle it may lead to huge unnecessary recalls and redundant investigation of defective and wrongly marked parts. The unidentifiable part, if found to be defective, cannot be traced while it leads to disaster, resulting in negative reputation of the brand value.

The data is easy to record with Flexible I/O Port. The Flexibility of recording the communicated data makes the system more reliable for our OEMs.

2D datamatrix code right pattern selection

From the predefined template, the 2d Data matrix code is cross checked with the ideal Data matrix pattern . It checks each value with the standards defined in the rule book of Automotive international standard of traceability. There could be various patterns which define the grade of the datamatrix code over the automotive part.

The patterns are ideal patented patterns that follow the ISO standards (its inbuilt in the Vision software

Laser Marking, Datamatrix code Reading, and Image Capturing and Saving Directly to PC

Once the Laser Marking is carried out, the inbuilt Data matrix code reader reads the 2D Data matric code and extracts the 2D characters by decoding the Unique code. The datamatrix code on the surface will be captured by the vision camera and saved to the PC attached to it, which is further updated to the database in the management software.

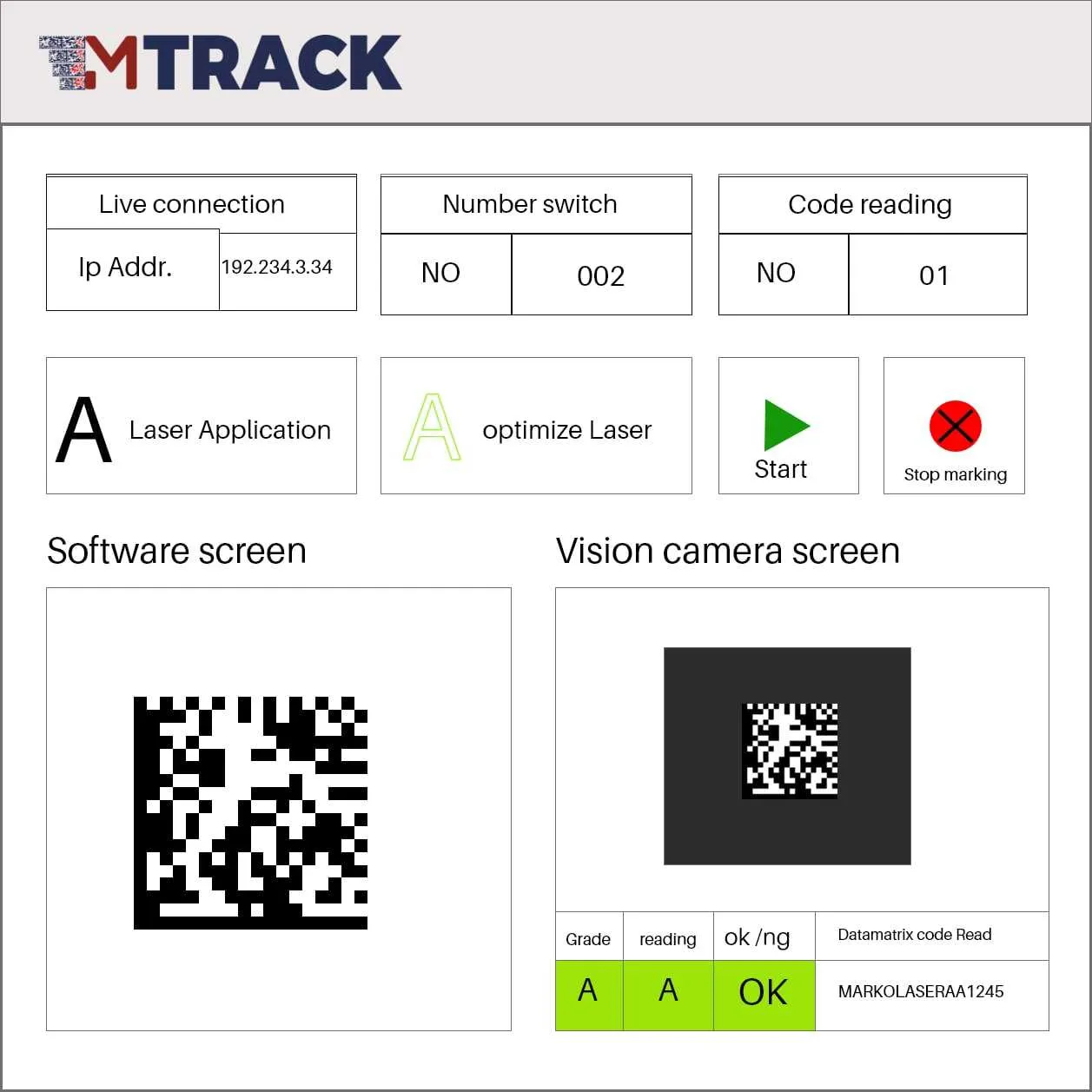

Flexible graphic User interface for grading and Capturing the data:

The User interface for laser marking control, Reading the data matrix , Capturing it and customizing according to the use ,flexibility and user friendliness of the Customer and operator.

How the Laser operation will be taken care of and how the complete operation will take place with the right operational button on the screen.

It means that the data to be marked will be received from the data base or the data will be manually fed to the system. All these factors will define the type of interface we need to make for our user.

Once the answers to these question are with you, we need to make this understand to our USER INTERFCAE Designing expert and Software development department.

The customized Software and interface will be developed specially for our customer. The vision camera will read the 2D data matrix code engraved on the surface of the object. The Data matrix code is then captured with the vision system and is saved to the data management software for future reference.

Traceability with MarkoTracer (Laser Marker and Unique code reader)

Markolaser Manufactures Laser Markers/engraver and integrates Data matrix Code reading vision camera for OEMs to Mark The data matrix code and to read them simultaneously thus proving to be the most reliable and easy to use Traceability solution provider for Automotive Original Equipment Manufacturers. Markolaser provides Data management software for the control of manufacturing process and creating Codes that follow the automotive environmental conditions as per the industrial ISO/IEC standard Tr 29158/24720.

Stability in Reading the Data matrix code

The Advanced Filters integrated in the Code Reader or the vision camera helps in eliminating the hindrance and difficulty at the time of reading the code. The Code reader is fixed in such a way that there is no need of special Angular Light that increases Illumination to Read at any environmental conditions. The Camera has a greater capability of Autofocusing on the object so that it can read the data matrix code with ease and flexibility.

The code reader is capable of Automatically adjusting the color contrast giving best results for reading the code.