A fully automatic Numberplate and nameplate marking and engraving Machine

A nameplate/number is widespread, it is an essence in almost every industry. For example, the path monitor and direction CARD, seat card, and product technical specifications and parameter nameplate. What is the best way to render these nameplates? Screen printing, CNC machining, or laser engraving, and We need to see into all the options.

Screen printing technology a prominently used method for printing plastic cases, which requires a screen mesh, screen printing machine, and unmistakable inks for printing. The CNC method necessitates using a CNC machine and is mainly used for metal engraving, cutting larger sizes for making giant artwork, and signboard. A laser marking and engraving system is needed, and it can be on a variety of materials such as plastic, wood, metal(ss, copper, gold, silver, etc.), ceramic, glass, Glass-filled plastics, and so on, after Comparing the three approaches. Laser engraving/marking seems to have a broader scope and is more environmentally friendly.

Almost every industry requires nameplate engraving and marking machine/system. There are two effective methods of engraving or marking a number plate or a nameplate used in today's world marking: dot peen marking and laser engraving machine. Although some traditional manufacturers still use the old manual pantograph system or computerized rotary engraving system. But the majority of industrialists from the automotive and electrical power sectors who supply their equipment to OEM use laser engraving machines or a dot peen system. Some use the hybrid nameplate engraver where they integrate Laser marker/ engraver and dot peen. This article will make you walk through the different nameplate marking techniques and how using an efficient machine will help you develop your market. and application

The Need for Nameplate Engraving/Marking

The demand for industrial manufacturing, production, and product identification has increased among numerous manufacturers. It is because most companies like to see their brands as traceable brands but still making them distinct in many prospective buyers' minds.

Furthermore, there are also industry compliance standards that enable companies to brand their equipment OR products. With so much competition in the industry with so many product choices available to meet the demands of consumers, product labeling is more crucial than ever.

Application of Nameplate and numberplate laser Engraving and marking Machine

When we look at the market, we can see that many businesses use nameplate plates marking, engraving and branding. The following are a few businesses that heavily rely on nameplate engraving techniques:

Aviation and Aeronautical Industry

The aircraft industry is a significant user of nameplate labeling techniques. That is because the rules demand that each and every section of the airplane be individually numbered. As a result, the aviation industry is constantly in search of strategies to identify their materials.

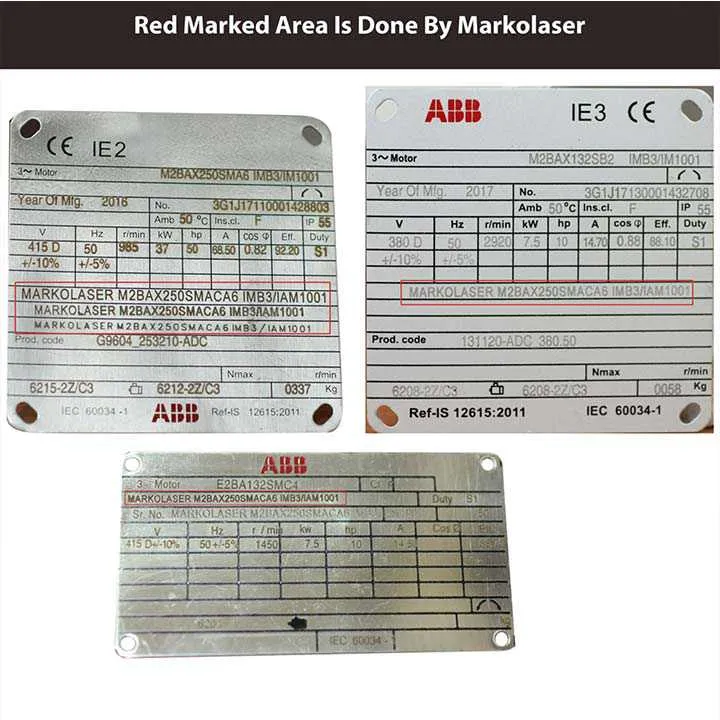

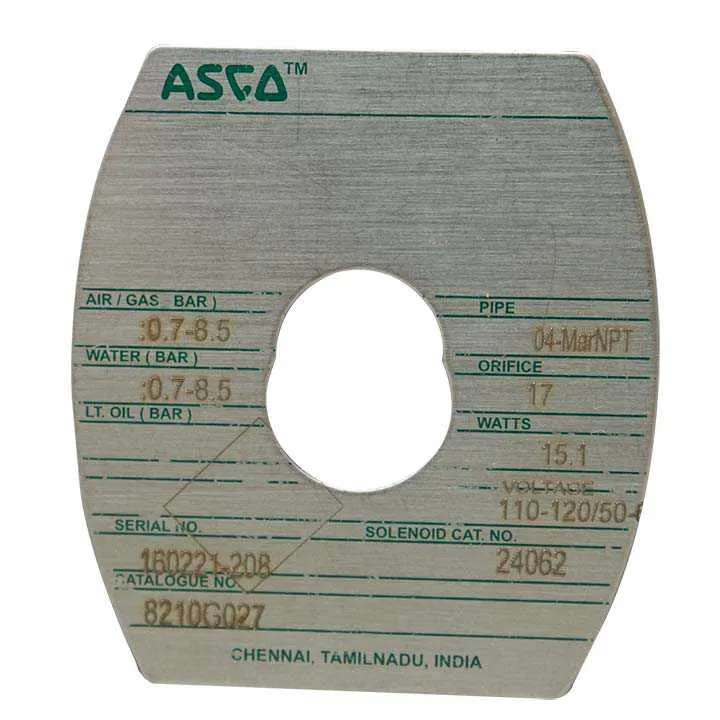

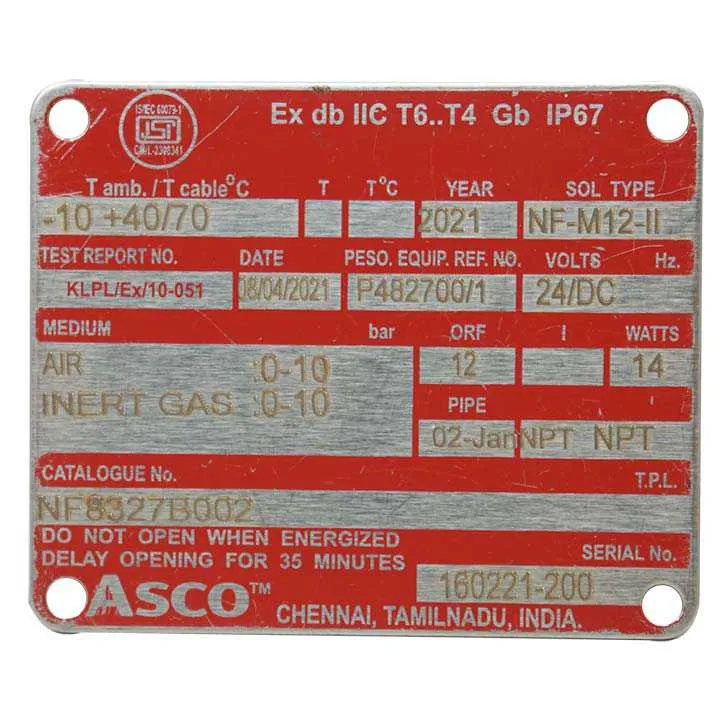

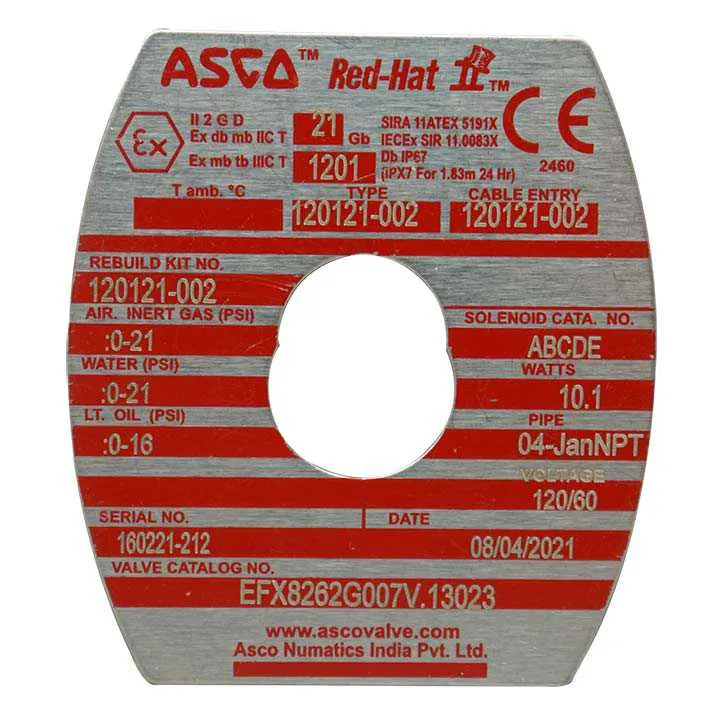

Motors, generator, and Power Generation Industry

The engine-making sector is another important industry in this regard. Motors are usually required to have a nameplate attached to them so that the operator can determine the motor ratings. It would be impossible for the operator or maintenance workers to operate on the engine if it does not have the branding or engraving of technical specifications. If the technical specification is not present on the machine and the operator makes some error, it leads to many hazardous problems. These motors are used in agricultural activity and construction activity for pumping water. Laser marked to become the essential part.

Automobile Industry

Nameplates are still widely used in the automotive industry. These nameplates specify what each part of a vehicle is for and the manufacturer details, part number, serial number, and so on. It helps in identifying the Defective part in the future and helps in recalling that exact part. One of the best examples is security plate marking; thus, the auto industry cannot ignore the importance of making an engraving machine. As a result, using an engraving machine in the car industry is a must.

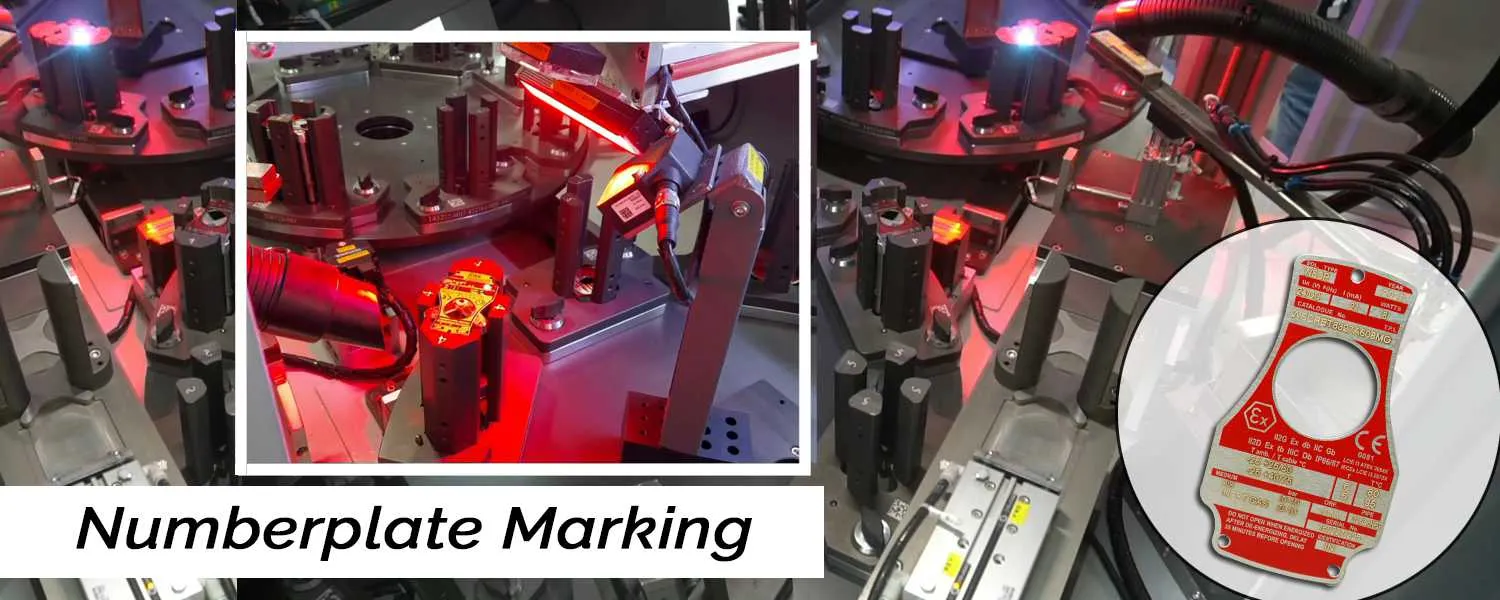

High-speed Laser engraving on Vehicle Security Number plate

We have designed this High-speed Mark on Fly laser engraving machine, which is integrated with the laser engraver, a part sensor, and a customized user interface connected online with the Database management system.

The Vehicle number plate is fed over the high-speed conveyor belt. There is a part sensor just before the laser marker. The Part sensor will identify a part just before the laser engraving if there is no part, the laser won’t fire. If there is, only then will the laser fire. The data which has ti be marked are extracted from the database and server. The two-way communication where the laser will be fed with the required information and once it is done. The feedback system will provide the request that the laser marking is done on the number plate.

https://www.youtube.com/watch?v=7cFXoJtabI0

Medical Industry

There are two kinds of laser marking systems in use in the medical industry. One method is direct component Marking, which is specific to medical instruments. And the other is device identification. Nameplate labeling is a standard method for marking devices for medical purposes. Ventilators, dialysis machines, and other medical devices fall under this category. As a result, having an appropriate nameplate labeling machine is a must for medical industry manufacturers.

Apparel and Decorative Industry

Decorative items all around the world are now being personalized to meet the needs of their owners. The majority of people choose to have their names engraved on their decorative items. As a result, in such cases, the nameplate labeling machine comes in handy. Leather belts, clocks, glass ornaments, and other decorative items are examples of decorative items.

Markolaser a Nameplate Marking and Engraving systems provider

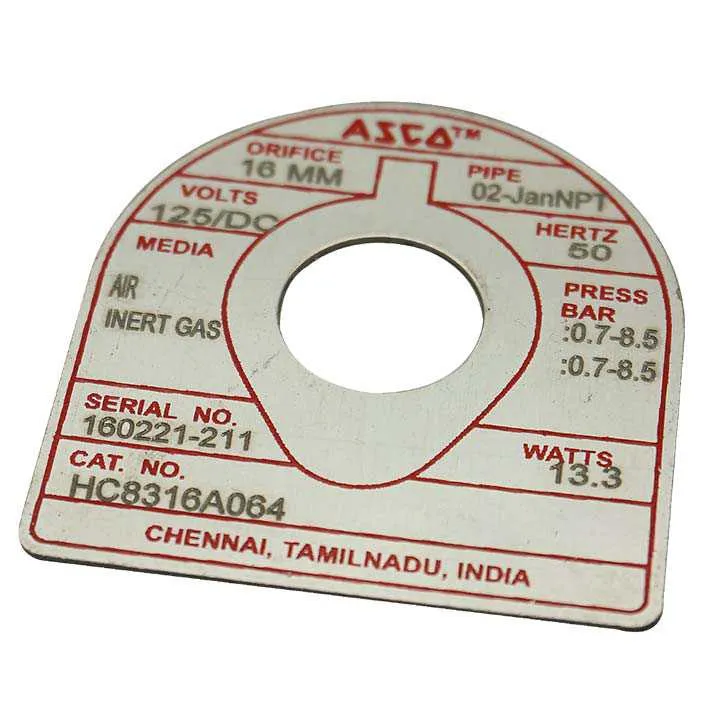

Markolaser is the manufacturer and distributor of various markers and engraver systems to have a permanent mark on nameplates and metal tags and sheets with the date of manufacturing codes, serial numbers, unique numbers, brand logos, graphics, or any sequence of characters and numbers.(alphanumeric code)

Types of Name Plate Marking Machines

Fully Automated Laser engraving Machines with nameplate shuttle feed systems

Permanent date codes, serial numbers, 2D data matrix, 2D barcodes, labels, or any sequence of characters and numbers can be imprinted on metal tags and nameplates using Automatic nameplate labeling marking mechanism.

To develop fully automatic nameplate marking, Markolasers engraving machines, scribe marking machines may all be fitted with nameplate shuttle feed systems & pick and place systems. These systems are customized and automated according to the customer’s requirement and production, and price. We know how to optimize the cost according to customer need without compromising quality and service support.

Semi-Automated laser marking Machines with fixed and adjustable, and flexible nameplate clamping mechanism

Manual Presses with Dies - We provide Dies for marking on Nameplates The highly precise laser engraved punch die for nameplate marking. This Laser engraving machine is comfortable and ergonomic, Very easy to operate and effortlessly. Helps in developing dies for great-looking valve tags, dog tags, or nameplates.

For more contact us know

CASESTUDY

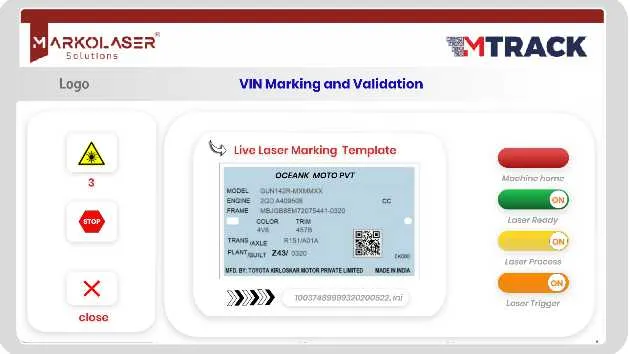

VINmark Laser machine is special developed with integrated Vision camera for validation and verification of Qr code/1D code on the Vehicle number platecode/1D code on the Vehicle number plate

Complete package consist of

- VINmark Laser machine: VIN laser marker mark according to the template and the data fed to the laser system from the database. The database management system has all the data being fed into the system from cloud server like SAP or oracle etc

- VIN and Mtrack Software(Traceability software)

- This customized software is specially developed according to the customers requirement. The software generates a QR code according to the data fed . all the Data on the plate will have a unique code. This unique code is traceable and scannable with any scanner.

- Markomark (Laser marking software) : The Markomarker laser marker is well integrated with Mtrack software. Where it very flexible to accept any type of alpha numeric character it may be manufacturing date and manufacturer name, part name and model number, frame number, Plate number etc

- Vision camera for Verification and validation

A fully Automatic Nameplate marking machine

- It is one of the specially designed number plate marking machine and automation.

- The data that needs to be marked is fed into the system

- Every day at the starting of the day, the data from the database is received.

- And the operator assigns the required data to be marked to the individual Variation of the number or nameplate.

- The Laser Markes the Numberplate with Smart Autofocusing mechanism.

- Once it detects the correct number plate on the right station, it starts marking.

- If the part is not appropriately kept, the variant is different from the original; if it is flipped, then it will be Separated out to the not ok bin

- After the marking is successfully done, the nameplate will be placed in the unloading station.

- The separator is integrated into the system to segregate two or more same variant with different data to be marked

- It is entirely an automatic laser marker with no need for human intervention.

- One of the most reliable and flexible marking machine with a robust mechanism and rugged body that can resist any harsh environmental conditions