- Have any questions?

- +91 9210626626

- info@markolaser.com

Laser Marking, Engraving, Micro-Drilling & Fine Cutting Machine for Watch Industry

High Definition

Ursa can create small, detailed geometric shapes with the utmost precision. This marking process cleans the material after processing and also provides the marking greater contrast (e.g. Data Matrix Codes).

Versatility

It can be used for laser marking, engraving logos with any font of alphanumeric character, bar-codes, unique code. These could range from data matrices, QR codes, bar-codes, progressive numbers, designs or artwork and graphic. The design could be simple or most complex.

Speed

Laser marking is a fast process offering unmatchable quality. It allows the creation of different types of markings (e.g. serial numbers, logos, codes) in extremely short time frames without having to re-fit the machine.

Traceability

Watch traceability is forever guaranteed since laser marking on the metal part of the watch is permanent, corrosion resistant and it resists both wear and contact with acids or heat. The contrast black marking of logos, information & 2D codes on stainless steel is easy with Markolaser.

Seamless Markings

It is possible to achieve completely seamless and indelible markings on various kinds of materials: the tone is achieved not via removal but rather through localized heating of the material.

Efficiency

It does not involve any costs for consumables such as inks, pastes or sprays and no costs for their expensive disposal. No prior or subsequent treatment is required. The equipment has no wear and tear problems.

Laser Engraving, Cutting, Marking Applications on Watch Parts

When it comes to the application of lasers in the watch industry, the marking, cutting and engraving on watches needs to be precise. Our lasers are the best in the market for cutting, marking and engraving on watch components. Below are some of the applications of lasers in the watch industry.

Laser Marking on Watch Components

The watch industry uses laser machines for marking part numbers, serial numbers, data matrix codes, decorative markings such as logos and graphics on watch components such as clockwork components, oscillation weights, bezels, crowns, housings, watch case backs or dials. The black marking on the back case of a watch is done with higher quality contrast.

- • Laser marking with Orion

- • Laser marking with Minnie Traceability

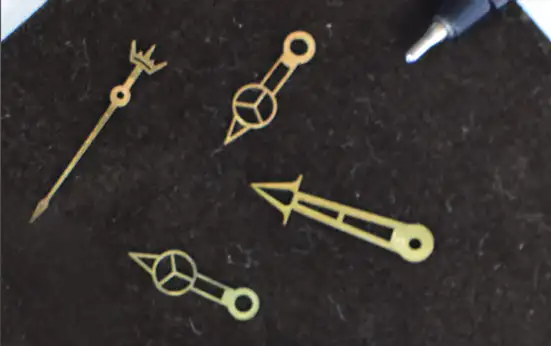

Laser Micro Cutting of Watch Components

Laser is used for micro-machining of gear-wheels; links; hands; inner plates etc. Short laser pulses with very high pulse power generate such high energy densities that the material usually evaporates immediately (sublimates). In this process, the idea is to use the laser to vaporize the material with as little melting as possible. Each laser pulse produces a small depression, typically measuring in few micrometers in diameter and just a few micrometers in depth.

- • Laser cutting with Ursa

- • Fume extractor, gold collector

Deep Laser Engraving on Watch Components

Deep laser engraving on watch inner plates, bezels etc. Deep laser engraving requires consistent laser focusing throughout the depth.

- • Laser cutting with Ursa

- • Fume extractor, gold collector

Laser Texturing for Watch Moulds

Laser is used for engraving textures on watch strip moulds and other moulds. Laser texturing on watch strips, bezels and inner plates for aesthetic looks.

- • Laser cutting with Ursa

- • Fume extractor, gold collector

Gear Cutting

Strap Die

Brand Marking

Punch Die

Bezel

FAQs