- Have any questions?

- +91 9210626626

- info@markolaser.com

Best Deep Laser engraving

machine and How to choose them?

The OEMs or the manufacturer for industrial products are looking for a Deep laser engraving machine for metals. The engineers call them by many names like Laser engraver and deep engraver for hard metals.

The deep metal laser engraving machine has a highly concentrated beam of light to engrave any surface; It may be the 2D or 3D surface on the metal.

Hard metals such as stainless steel, alloyed copper, alloyed brass, iron are very useful in industrial applications.

The applications by deep engraver on these hard metals solve many of their problems, thus gives us the right solution. Moreover, precious metals such as silver, platinum, gold are used in Jewelry Market need deep engraving as per the customer demand.

All the metals are deeply engraved as per the need and demands of the respective market.

Understanding Deep Laser engraver and Laser

engraving concept: What is a deep engraving?

According to our application Laser engineers, Pulsed fiber deep engraving lasers give the best solution to fulfill all the marking needs of OEMs. The beam engraves deeper and is helpful. The laser can reach the peak power and are deep enough to give the right depth that stays forever. In addition, the engraving is clean and sharp and follows all the industrial standards.

Laser engraving applications and deep engraving applications are very similar. It is another way of calling an engraving laser. When we increase the power and need a much deeper marking on metals, we give it a name as Deep engraving.

Deep engravers take just a Lil bit more time to create an impression on metal components and Instruments. However, the engraving depth is so clean and impressive that it gives a significant visual effect and a great touch feel.

If you are looking for a deep marking application and need to have the right depth on your metal, you have come to the right place.

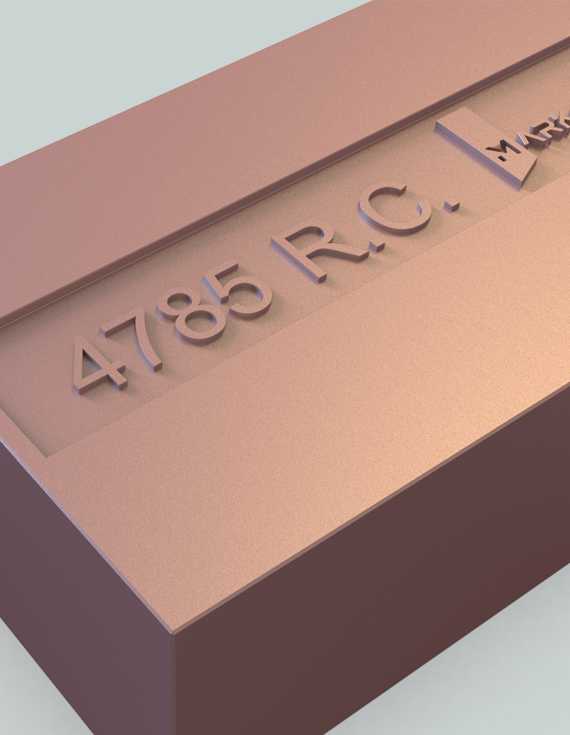

Unique Code Engraving

Engraving on rough surface

3D, Step Engraving on Metals

How much deeper can we engrave with Laser

deep engraving machine?

When we want Laser deep engraving on metals, we need to crave the metal surface bit deeper, near to few millimeters over the metal surface.

Removal of few more microns of iron from the top surface of the metals is known as Deep engraving.

Typically a standard Laser engraving will engrave the metals up to 500 microns.Generally, in the automotive industry, the metal auto parts need to be traced with correct depth. However, sometimes they are deep enough to call it deep laser engraving. As the automotive parts need traceability, the Datamatrix code needs to stay forever and resist the inline factory process. Such as Oiling and shot blasting. Markolaser laser engraving technology is so sophisticated that after shot blasting or oiling, the laser engraving won't affect the quality of code on the metal Auto part. To create a fundamental difference between deep engraving and laser engraving, depth becomes the most crucial factor which makes the right graphical aesthetic over the metal components. Automotive, Medical, and aeronautical traceability standards require great depth and contrast while marking. UDI Laser marking on Medical products must not be deep. In addition, it must be dark and corrosion-resistant.

What is Deep Engraving Used For?

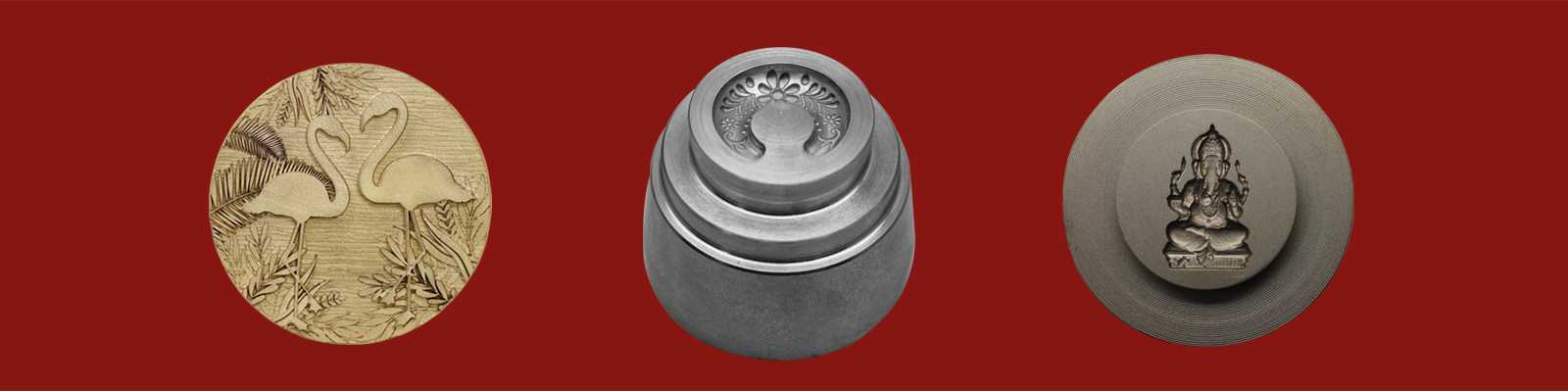

Deep Laser engraving has many applications in the jewelry industry, Tool industry, Coin making, Aesthetic industry & Shoe industry.

2D deep Laser engraving and 3D deep Laser engraving on 2D and 3D metal have many applications.

2D/3D logo engraving on metals part or laser Hallmarks on Gold, Silver, platinum jewelry.

Laser deep engraving machine for marking on jewelry. Engraving text and artworks on gold jewelry. Laser Engraving of Number and Alphapates.

In the Automotive, Tool, and Aeronautical industries, traceability has great significance. Laser marking of Serial number, Alphanumeric number for identification is beneficial for counterfeiting, reducing recall, and increasing brand reputation. The Laser engraver must have excellent repeatability and must be precise and uniform all over the metal surface.

Punch dies are critical applications that need utmost precision to create a small artwork on the metal surface. Pad printing machines need Dies that are engraved deeper so that ink can deposit well on the engraved part. As a result, the pad will pick the inks perfectly. Mold inserts engraving is very famous and is of great importance in the automotive industry.

Deep engraving on Nameplates, These nameplates are attached to the aerospace parts and sections. The nameplates give us all the technical details of the particular section in the aircraft or jet. Nameplate engraving is a beneficial application in huge electrical motors, generators, and inverters used in the high production industry. It tells and instructs the operator about the alert and the actions needed in an emergency.

Laser 3D and 2D textured engraving is a very useful application in many industries. We help all of them with our premium laser engraver that creates such intricate laser engraved designs on the metal surface. Thus, from the above application, we can say that the laser deep engraving process is helpful in a wide range of industrial applications and has many benefits.

Can You Deep Engrave on metal Stainless Steel?

Laser engraving on Stainless steel needs the right laser machine with the right specification and integrated technology that is capable enough to engrave deeper on the metals. Combining all the engineering components such as lens, optics, scanner & source with perfect specifications creates the right engraved logo or marking on the part.

The technical operator skills plus the design file must have all those technical features to create an impressive, visually appealing component.

To make a die, it may be a punch die or a coin die or insert mold die; the stainless steel of High HRC value is needed so that it will have a longer life. Deep engraving on these hard metals is not an easy job. It requires outstanding engineering research and development with years of experience. Laser removal of the oxide layer of rusting needs a lot of experience. We have to play with frequency and power to achieve clean results. Stainless steel components will change their color according to the configuration. Therefore, an operator must have knowledge & experience to understand the correct technical details that will change the formation and marking on the SS metals. There are applications like you want to have a blackening effect on the SS metal component. Or you want to clean the surface of the SS metal product. For example, you might be interested in removing the upper layer of the coating of plastic and metals. All these applications are possible with a Markolaser laser engraver with precision and efficiency.

3D Engrave on metal Stainless Steel

When it comes to 3D engraving and texturing on the 3D Stainless steel components, it requires the right engineered Laser engraver.

The DFX file fed to the laser is made with utmost precision and has the right engraving depth in the software interface and settings. The 3D coordinates must have that perfection that is only possible with the right design and the right calculated depth of engineering.

Understanding metal's hardness and the proportion of metal mixed with it, the placement of the SS component, and many more factors will define the quality of marking on the metal surface.

We at Markolaser solutions believe that if a customer comes to us, he will get the right engineered product. We promise not to serve an over-engineered product. Our results and output are precisely engineered creation, which creates value and has a great impression.

What are some essential parameters we must take into consideration at the time of laser engraving?

Right Laser engraving Power and specification

While choosing a suitable engraving laser, One of the vital parameters is the laser power, which decides the cycle time if you have high production. Therefore, if you want to mark with high speed, you need to set a high-power laser into the system to fulfill the production requirement. Only if you increase the power value can you match the speed of production. Therefore, good quality with the right speed is a must and need of industrial business. A 700 wattage laser engraver doesn't mean seven times faster than a 100 wattage laser engraver. But will be faster and will offer open flexibility to speed up the process. According to our Laser application expert, the most deep engraving applications require at least 70 to 100 wattage lasers. We at Markolaser provide all the range of high-power laser machines according to the application requirement. It may be 70 watts to 500-watt laser; we will serve you the best Laser engraver that suits your application and fulfill your production's needs. We also think about your economy. Deep engraving is possible with an engraver of 70 watts or lesser value. But that will take a longer duration to engrave. So if time is not a factor that affects your cost of production and you have fewer parts to engrave, the low-power laser can also fulfill all your application needs. We serve the best laser to the industry. We always think about our customers. But the premium lasers come with premium cost. We believe in serving the best with no if and but in the quality and service.

Supreme Lens for Perfect Laser beam quality

You would be astonished, and it will sound funny to hear that laser power is not an essential factor in achieving high-speed engraving. The Optical lens integrated into laser systems is more critical and one factor that decides the deep engraving on the metal surface. Right focusing and controlled focus on the metals. A deep and highly precise focused laser beam with the right intensity will decide how effective the artwork comes out. And if we use the right engineered lens, it will double up the speed of engraving on metals. The Laser team has experimented with all the different lens values such as 160 mm, 254mm, and 420 mm lenses. The experiment shows that the laser engraver with less lens value is more precise and deep to create perfect metal engraving.

Laser Deep Engraving speeds for a 100W fiber laser machine.

160 mm lens on aluminum 0.75—1.37 mm3/s

254 mm lens on aluminum 0.42—0.71 mm3/s

420 mm lens on aluminum 0.23—0.38 mm3/s

160 mm lens on steel 0.06—0.14 mm 3/s

254 mm lens on steel 0.05—0.11 mm 3/s

420 mm lens on steel 0.04—0.09 mm 3/s

Laser engraving Scanning Speed

Every laser machine has a scanner inside it. It is an integrated part of every engraver. The speed with which a laser beam moves over the surface of metal or non-metals is called laser scanning speed. Low laser scanning speed implies that the laser beam is concentrated on the metal surface for a longer duration. As the laser beam is concentrated over the surface of the product for a longer duration, it will result in an increase of concentrated energy on the surface of that metal component. The increased energy will all deep laser engraver to engraver deeper and with high speed. Sometimes the laser beam is uncontrollable that generally happens with the conventional cheap laser engraver. This may lead to discoloration and irregular engraving and burning of metals surface. Premium Markolaser engravers are flexible and are integrated with advanced technology. With great control over the scanning speed, it could be slow or fast. It allows us to create beautiful deep engraved artwork or logo with the right quality of cycle time to fulfill the requirements. In our R &D lab, we perform applications according to the need of the customer. We experiment and propose the best results with the right balance between speed and quality.

What Laser Engraving Machine Do You Need?

Standalone Deep laser engraver

for metals with Class 1 cabinet

The deep laser engraving that we serve to our customer are standalone, and it is a class one laser engraver. A rugged laser engraving machine that can withstand any industrial environment. A class one cabinet with all safety majors. There is always an emergency button to stop to process. The deep laser engraving has high power lasers, and it takes a longer duration to create the artwork over the metal surface. The laser sparkes may affect the operator therefore, for the safety of the operator, it requires a safety cabinet. Deep engraving machines are less expensive than other types of equipment. since automation is not required. All you have to do now is start the procedure and then return to load a different component once it's finished.