Frequently asked Questions?

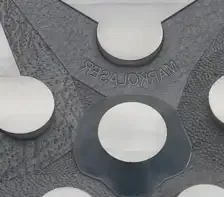

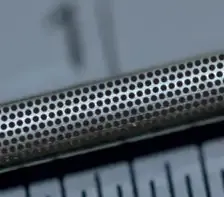

Ans: Yes! MarkoLaser’s laser engraving machines—especially those with fiber or hybrid laser—can engrave across multiple materials with precision and consistency. They can do metal engraving deep and permanent marking on steel, aluminum and copper. They can also engrave wood for artistic designs, logos or names. For glass controlled laser parameters can do smooth surface etching without cracking. For plastics and acrylics the laser can do clean and sharp marking with the right wavelength, no burning or deformation. These multi-material capabilities make MarkoLaser’s laser engravers most versatile in the industry.

Ans: Different materials require different laser sources to achieve the best results. A fiber laser engraver is best for metal and some industrial plastics, high precision and depth. CO₂ laser engraving machines are best for non-metallic materials like wood, acrylic, rubber, leather and even glass. For very delicate materials like thin plastics, PCBs or glassware used in electronics a UV laser engraving machine is the safest and most accurate option. By choosing the right laser type MarkoLaser ensures each application will deliver great results, whether for artistic customization or industrial traceability solutions.

Ans: Yes, a well equipped laser engraver from MarkoLaser is versatile enough to do both industrial and high-end custom applications. For industrial use our laser machines are used for marking parts, tools and components—engraving serial numbers, barcodes and logos with high accuracy. At the same time the same machine can be used for engraving jewelry fine detailing and deep marking on gold, silver and other metals. It also works great for custom gifts like engraved wood nameplates, glass awards or personalized rubber stamps. This versatility makes MarkoLaser’s machines a smart investment for anyone who needs multi-purpose functionality.

For More Information Contact :- info@markolaser.com