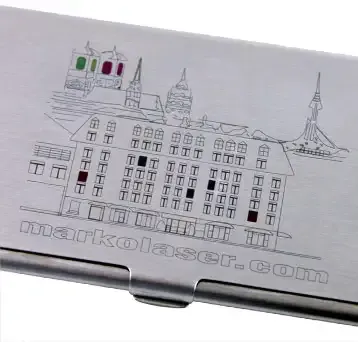

Applications of Laser Marking on Metals & Plastics

Laser marking | Laser annealing | Laser foaming | Laser carbonization | Laser branding Laser application on metals such as copper, aluminum, stainless steel, brass, gold, silver ; non-metals such as diamond, wood paper, plastic(Nylon, PP, PVC, PE, Teflon, PPE, ABS)

Laser Marking and Paint Removal on Precision Scale Dial Indicator

Object Name : Precision Scale Dial Indicator

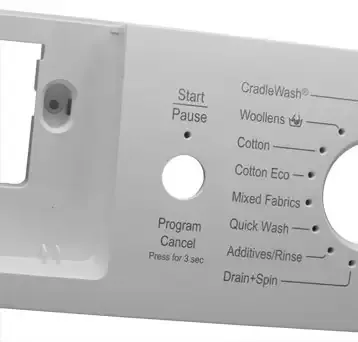

Laser Marking on Sliding

Vernier Scale

Object Name : Sliding Vernier Scale

Annealing Laser Marking

Annealing marking is an oxidation process used on carbon containing metals by applying heat through laser on the surface of any metal. Annealing marking generally gives a black mark with a smooth finish, but color may vary from brown, red, green etc. depending upon the heat used for marking.

Some Key Points of Annealing :

Used on carbon-containing metals such as Titanium, Steel, Stainless Steel, Iron

Oxidation process can result in a variety of colors

A slower, more drawn-out process

Common in the medical industry applications such as internal tracking and branding

Carbon Migration Laser Marking

Carbon migration is another type of laser marking in which a metal or metal alloy is heated, causing metal to chemically bond with its carbon molecules. This bonding brings the carbon properties to the surface of your material. When this occurs, it will often result in a dark laser marking that can even be black. This type of marking is a faster process than annealing because it provides a high amount of heat to a smaller area within a more rapid time period.

Some of the Key-points of Carbon Migration Laser Marking:

Only metals and its alloys containing carbon such as steel, stainless steel, carbide, titanium can utilize this marking

Heating process migrate carbon to the surface

Produces dark markings

Heat is applied rapidly

Foaming Laser Marking

Foaming is a laser marking technique used only on polymers. Laser foaming is carried out by creating a molten burn on the surface. The molten surface creates an atmosphere of foaming gas bubbles. Foam laser marking is usually carried on a polymer which results in a light color.

Some of the Key-points of Foaming Laser Marking:

Used only on polymers

Produces light & smooth markings

Material is melted, creating foam and gas bubbles

Coloration Laser Marking

Coloration laser marking is the process of adding color to a polymer or metal by controlling laser and scanner parameter such as pulse frequency, pulse width, power, speed and more. Coloration on polymer occurs by foaming process while it occurs via oxidation in metals.

Some of the Key-points of Coloration Laser Marking:

Can be utilized for both metals and plastics

The process for coloration varies, depending on your material

Creates contrast in both colored and black and white materials

Color results are based on an oxidation process