- Have any questions?

- +91 9210626626

- info@markolaser.com

Femtosecond laser

Femtosecond laser technology has emerged as a game-changer in the world of laser technology. It is a type of laser that emits ultrashort pulses of light, typically of the order of femtoseconds (one quadrillionth of a second). These lasers are known for their ultrafast and precise performance, making them valuable in various scientific, medical, and industrial applications.

How does a femtosecond laser work?

Femtosecond lasers operate by generating pulses of light with durations in the femtosecond (10-15 sec) range. This is achieved through techniques such as mode-locking, where the laser cavity is designed to produce ultrashort pulses by synchronizing the phases of different longitudinal modes of the laser.

What are the key advantages of Markolaser femtosecond lasers?

High Precision:

Markolaser femtosecond lasers offer unparalleled precision, enabling micrometer and even nanometer-level accuracy in cutting, drilling, and machining processes.

.png)

Minimal Heat Affected Zone (HAZ):

Due to their ultrashort pulse durations, Markolaser femtosecond lasers generate minimal heat, reducing the risk of thermal damage to materials during processing.

Versatility:

Markolaser femtosecond lasers can be used on a wide range of materials, including metals, ceramics, polymers, glass, and semiconductors, making them versatile tools in manufacturing and research.

Non-linear Effects:

Markolaser femtosecond lasers can induce nonlinear optical effects, such as multiphoton absorption and two-photon polymerization, allowing for the fabrication of complex 3D structures and micro/nanoscale features.

Minimal Post-processing:

The precision of Markolaser’s femtosecond laser processing often reduces the need for extensive post-processing steps, saving time and resources in manufacturing workflows.

What are some common applications of Markolaser femtosecond lasers?

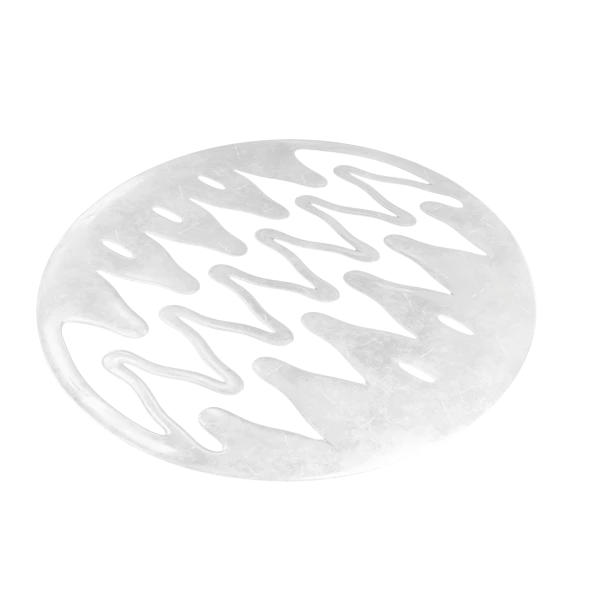

Precision Parts Cutting

Femtosecond lasers excel in cutting intricate and delicate parts with exceptional precision. The ultrafast pulses delivered by these lasers enable clean cuts with minimal heat-affected zones, ensuring high-quality results even on materials like metals, ceramics, and polymers. This level of precision is crucial in industries where micrometer-level accuracy is paramount, such as in the production of medical implants and microelectronics components.

Femtosecond laser structured sample used to study the influence of implant structuring on cells

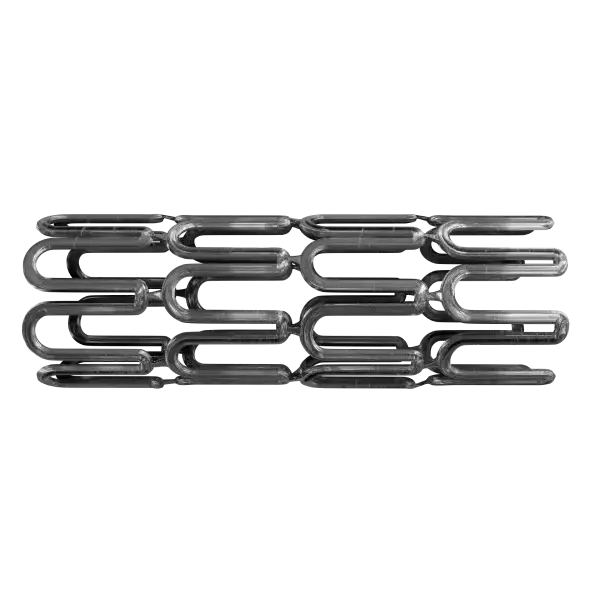

Metal cutting with Femtosecond laser

Glass Cutting & Drilling

Glass, known for its brittleness and difficulty in machining, poses challenges in traditional manufacturing processes. Femtosecond lasers, however, offer a solution by delivering pulses in the femtosecond range (one quadrillionth of a second), which allows for precise cutting and drilling without causing cracks or thermal damage. This capability finds applications in manufacturing glass substrates for electronic displays, cutting intricate glass components for optics, and drilling micro-holes in glass for sensors and microfluidic devices.

Glass drilling

Glass cutting

3D Milling & Polishing

The ability of femtosecond lasers to operate in three dimensions makes them ideal for 3D milling and polishing applications. By precisely removing material layer by layer, these lasers can create complex 3D geometries with sub-micron accuracy. This capability is leveraged in the production of molds, dies, and prototypes, where intricate designs and smooth surface finishes are essential.

Micro & Nano Drilling

In the realm of micro and Nano manufacturing, femtosecond lasers play a vital role in drilling ultra-small holes with diameters ranging from micrometers to nanometers. This capability is utilized in manufacturing microfluidic devices, aerospace components with microscale features, and medical devices such as drug delivery systems and bio-sensors. The precise control offered by femtosecond lasers ensures repeatability and accuracy in these demanding applications.

Glass to Glass Welding

Femtosecond lasers enable bonding or welding of glass-to-glass interfaces with high precision and strength. This technique, known as glass welding, finds applications in the production of optical components, microfluidic devices, and hermetically sealed packages for electronics. The ability to create seamless bonds without introducing additional materials or adhesives is a significant advantage in terms of reliability and performance.

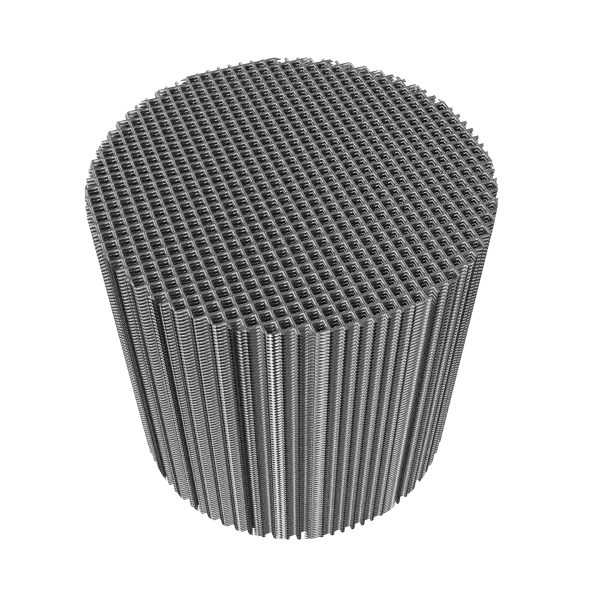

3D Additive Manufacturing

Femtosecond lasers have also made significant strides in the field of additive manufacturing, where complex 3D structures are built layer by layer. By using femtosecond laser-induced forward transfer (FLIFT) or two-photon polymerization (2PP) techniques, manufacturers can create microscale and nanoscale structures with high resolution and detail. This capability opens new possibilities in producing miniaturized components, micro-optics, and custom-designed structures for various applications.

3D cell Structure fabricated with 2 photon polymerization technology

What are the challenges or limitations of femtosecond lasers?

Complexity:

Operating and optimizing femtosecond laser systems may require specialized knowledge and expertise in laser physics and optics. Markolaser technology simplifies the operation and optimization of femtosecond laser systems by incorporating advanced automation and intelligent control features. This reduces the reliance on specialized knowledge of laser physics and optics, making the technology more accessible to a broader range of users. The intuitive user interfaces and software tools provided by Markolaser streamline the setup, calibration, and parameter adjustment processes, optimizing the performance of femtosecond lasers with minimal manual intervention.

Safety Considerations:

Due to their high power and ultrashort pulse durations, femtosecond lasers pose safety risks, necessitating proper training, safety protocols, and protective equipment for operators and users. Markolaser prioritizes safety through the integration of robust safety protocols and features within its laser systems. This includes automated safety interlocks, emergency stop mechanisms, and comprehensive training modules for operators. Additionally, Markolaser provides guidance on the proper use of protective equipment, such as laser eyewear and shielding, to mitigate the risks associated with high-power femtosecond lasers. The emphasis on safety protocols and user training ensures a secure operating environment and minimizes potential hazards for both operators and users.

FAQ's

Markolaser's femtosecond lasers offer advantages such as ultra-high precision, minimal heat-affected zones, versatile material compatibility, and the ability to create complex 3D structures with high resolution.

Industries such as microelectronics, medical device manufacturing, aerospace, automotive, and research institutions benefit significantly from Markolaser's femtosecond laser technology due to its precision machining, micro/nano fabrication, and additive manufacturing capabilities.

Markolaser's femtosecond lasers can process a wide range of materials including metals, ceramics, polymers, semiconductors, glass, and composites, making them versatile tools for various manufacturing and research applications.

Yes, Markolaser offers comprehensive training programs, technical support, and maintenance services to ensure users can operate their femtosecond laser systems effectively, safely, and achieve optimal results.

Yes, Markolaser's femtosecond lasers are designed to be compatible with existing manufacturing workflows and can be seamlessly integrated into automated systems for enhanced efficiency and productivity.

Typical applications include precision cutting, drilling, micromachining, 3D printing, surface structuring, laser ablation, medical device fabrication, and scientific research in areas like spectroscopy and microscopy.

Markolaser's femtosecond laser technology stands out due to its exceptional precision, ultrafast pulse durations, advanced control features, user-friendly interfaces, and comprehensive safety measures.

You can contact Markolaser directly or visit their website to access detailed information, product specifications, case studies, application notes, and request demonstrations or consultations to understand how their femtosecond laser technology can benefit your specific needs.

For More Information Contact :- info@markolaser.com